CASE STUDY: AUTOMOTIVE EDUCATION

Formula Student – Somos® PerFORM Tooling and Composite Layup

Case study of use of Stratasys NEO - Written by Maria Rubia, OBR19

CASE STUDY: AUTOMOTIVE

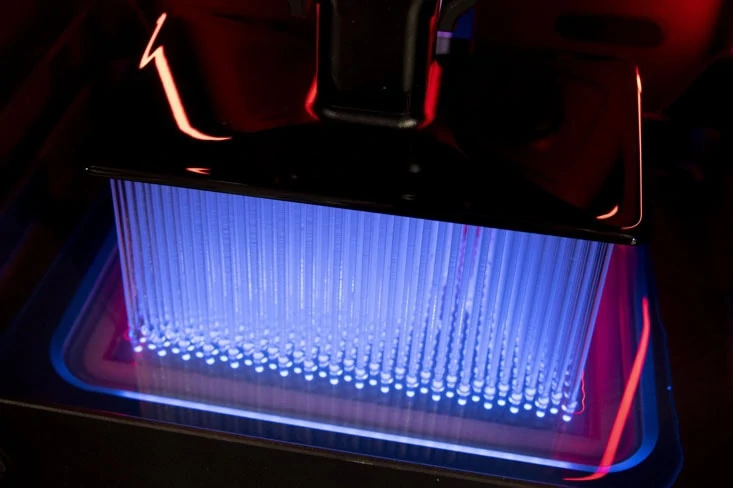

McLaren Racing — Advantage on the track with Stratasys Neo800

Stratasys’ Neo800 stereolithography 3D printers are enabling McLaren Racing to make up to 9,000 parts per year —...

CASE STUDY: EDUCATION

Brunel students enjoy design freedom with a new central additive manufacturing centre

Cutting-edge engineering and Brunel University are synonymous. Named after one of the greatest figures of the industrial revolution, the engineer Isambard Kingdom Brunel, the university has been at the forefront of technological education...

CASE STUDY: AUTOMOTIVE

1966 Chevy Impala restored with an Xact Metal machine

In 1980, a young car enthusiast named Tomme acquired a 1966 Chevrolet Impala after it had been damaged in a fire. The interior was ruined, and the dashboard had taken a beating, but the car still had life in it, and Tomme was determined to...

CASE STUDY: LOW VOLUME PRODUCTION

Goetz Maschinenblau

Mechanical engineering company, Goetz Maschinenblau, turned to the Stratasys H350™ to replace costly mould production.

CASE STUDY: MEDICAL

Ramping up to half a million 3D printed test swabs

When the COVID-19 pandemic hit, so did an urgent need for large supplies of personal protective equipment (PPE). Origin One 3D printers provided a solution.

CASE STUDY: EDUCATION

The AMRC is ‘ahead of the game’ with additive manufacturing and Laser Lines

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) is a network of world-leading research and innovation centres that work with manufacturing companies of any size around the globe. It specialises in carrying out...

CASE STUDY: LOW VOLUME PRODUCTION

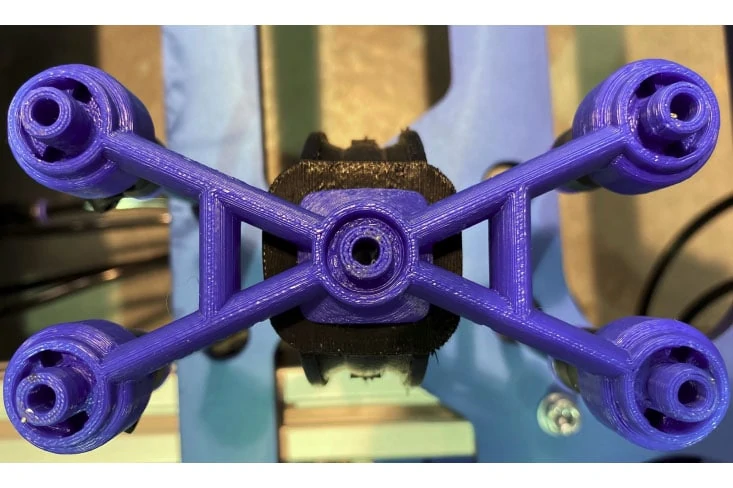

Form Automation

This robotics company relies on the Stratasys F370 3D printer to quickly and cost-effectively produce replacement end-of-arm tools for its network of robots.

CASE STUDY: AEROSPACE

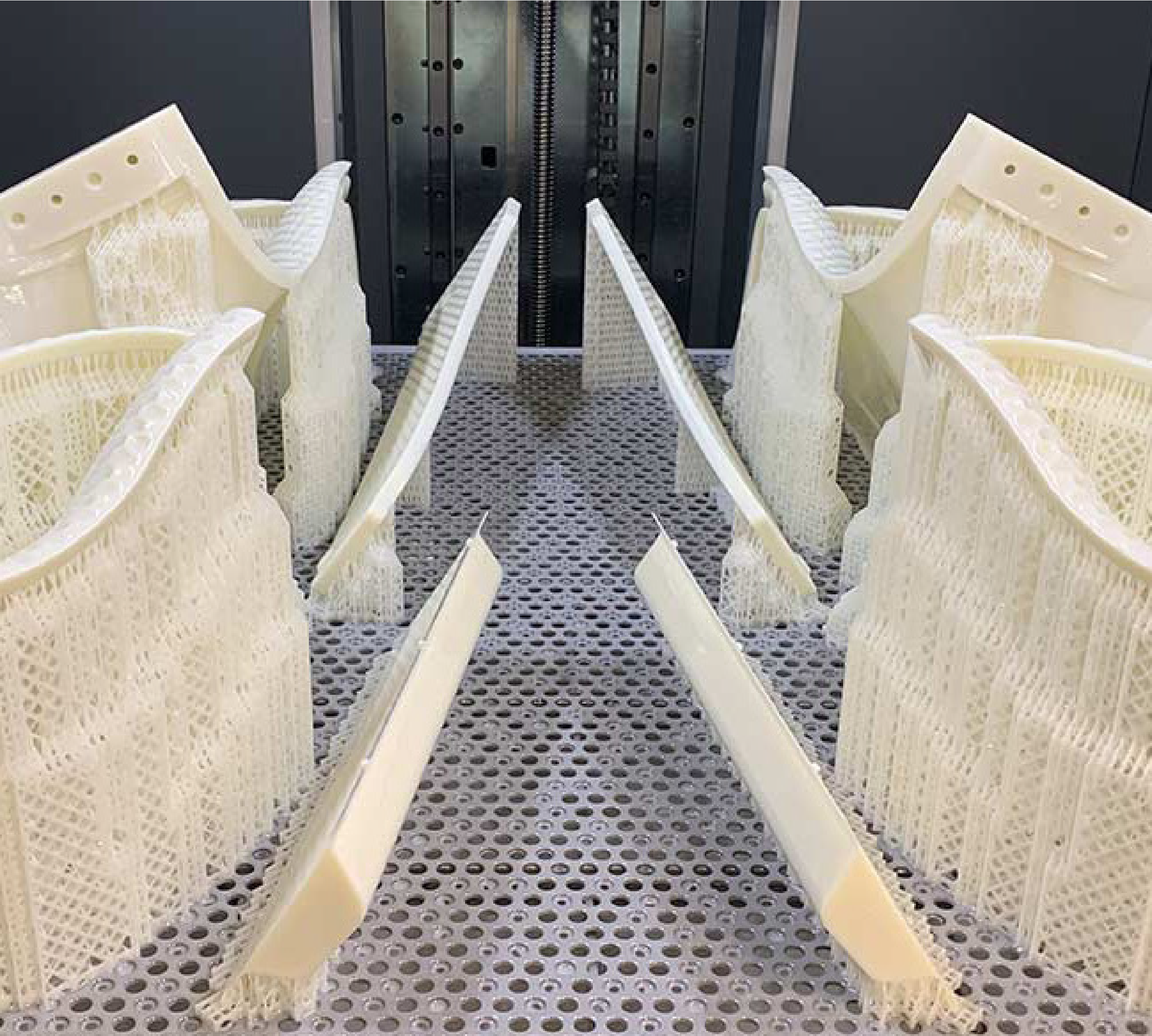

GKN Aerospace enhances tooling capabilities

“The F900 3D Printer offers us the enhanced geometric freedom to create previously unthought of 3D printed tools, which then enable us to manufacture extremely complex parts that would be uneconomical or just physically impossible to...

CASE STUDY: AUTOMOTIVE

Holly Mason and Ten Tenths receive superb support from Laser Lines

Ten Tenths is dedicated to keeping Nick Mason’s collection of road and competition cars in peak operating condition. The collection, that numbers around 35-40 at any time, spans pre-war racers right up to today’s hybrid performance...

CASE STUDY: CONSUMER PRODUCTS

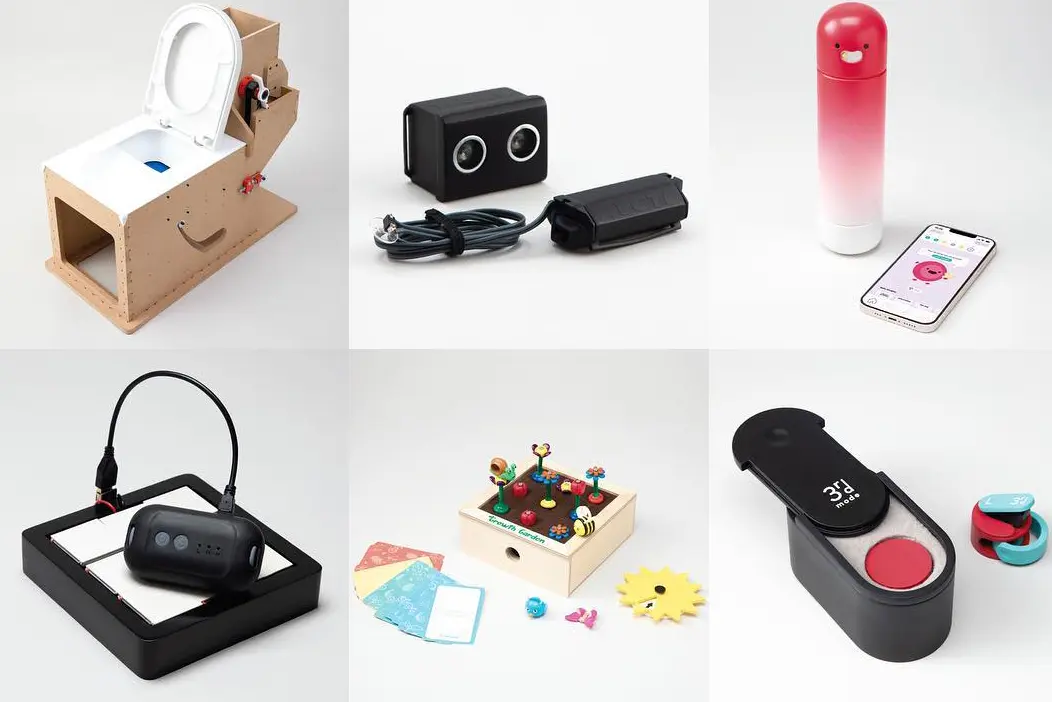

Center for Advanced Design

This product development firm has saved lots of time with a Stratasys F370 3D printer. Thanks to its minimal setup, fast draft mode and auto-calibration, the team now have more time to concentrate on designing.

CASE STUDY: LOW VOLUME PRODUCTION

VTT Technical Research Centre

How a Finnish company used the power of additive manufacturing to re-design a valve block that is 66% smaller than the original, saving weight, space and material.