FDM 3D Printers: Stratasys F900

Find out more about FDM 3D Printers

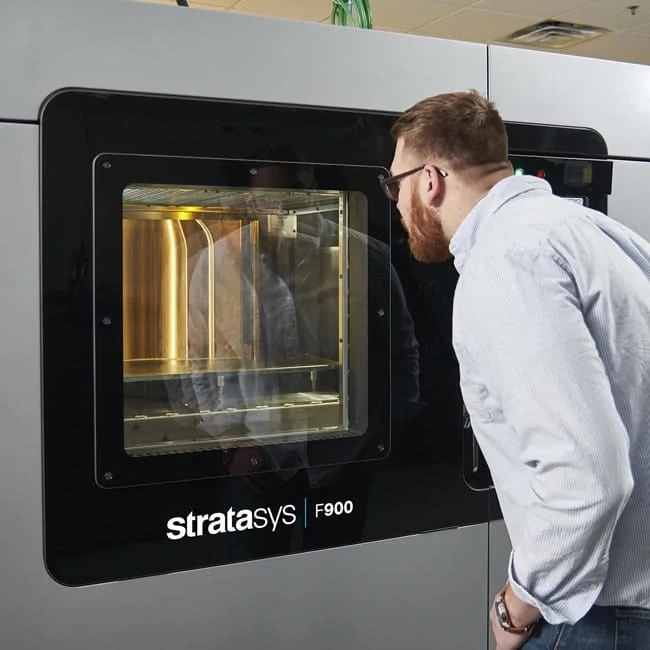

Stratasys F900

The Stratasys F900 is built specifically for manufacturing and heavy industries in mind. The Stratasys F900 has the largest build size of any FDM system, and designed from the ground up to work in the most demanding manufacturing environments for seamless integration.

Key features

- Faster build time for large parts: Add F900 Acceleration Kit to your system and scale up production and work flow.

- Enhanced efficiency and visualisation: Directly import your most commonly used CAD file formats into GrabCAD Print.

- Production phase optimisation: Insight Software allows you change your designs on the fly, revise production materials, and more, all without delaying your overall production schedule.

Automated production and monitoring

The F900 comes with remote internal cameras so you can view the part production anywhere, dew point monitor to maintain material quality and dual material bays and high-capacity material options and automated change over for continuous building.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

914.4 x 609.6 x 914.4 mm

-

SYSTEM SIZE

2772 x 1683 x 2027 mm; 2869 kg

-

ACCURACY

+/- .089 mm or +/- .0015 mm per mm whichever is greater

-

POWER REQUIREMENTS

230 VAC (three phase) 50/60Hz

-

ADDITIONAL REQUIREMENTS

Compressed Air 90-120 psi with a minimum flow of 20 SCFM

-

SOFTWARE

Insight and Control Center job processing and management software

-

MATERIAL OPTIONS

16

CASE STUDY: AEROSPACE

GKN Aerospace enhances tooling capabilities

“The F900 3D Printer offers us the enhanced geometric freedom to create previously unthought of 3D printed tools, which then enable us to manufacture extremely complex parts that would be uneconomical or just physically...

MATERIALS

The Stratasys F900 uses engineering-grade thermoplastics to build robust production parts, jigs, fixtures, factory tooling and functional prototypes.