FDM 3D Printers: Stratasys F3300

Find out more about FDM 3D Printers

Stratasys F3300

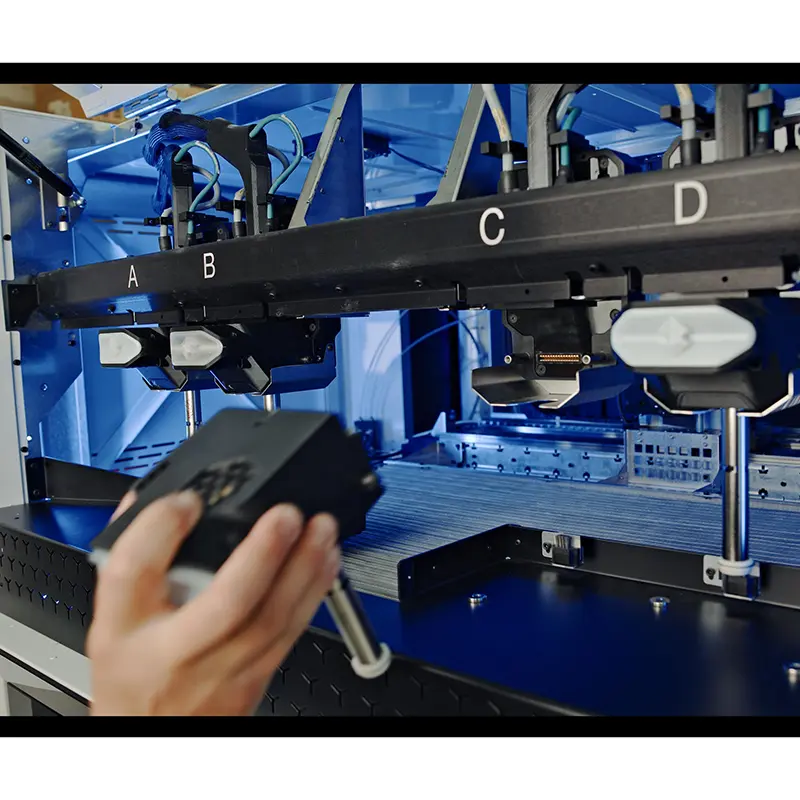

Meet the future of FDM-based additive manufacturing – the F3300 from Stratasys, the inventors of FDM. Using a next generation platform, the F3300 draws on decades of refinements, improvements and increased understanding to take FDM to the next level. The result is a new machine that has been re-thought from the ground up to produce FDM’s best ever results, with increased part strength, a higher throughput, improved machine reliability and better traceability. Thanks to the ability to have four loaded extruders at once, you can print parts in multiple colours and resolutions, while reducing swap times and increasing redundancy, with no changeover failures. These advances, together with the large 600 x 600 x 800mm build volume, makes the F3300 the ideal choice for production and high-end prototyping in the aerospace, automotive and defence industries, along with service bureaus.

Key features

- Four extruders can be used to print model or support material, as well as multiple colours and resolutions.

- Produces parts 2-3 times faster than a Stratasys F900, without sacrificing part quality.

- Dual axis technology means that the extrusion heads and the Z-stage move independently in Z of each other.

- Brand new, two-part extruders are twice as fast as previous generation extruders.

- Two cameras monitor a part’s progress, while multiple sensors generate data on all the motors and process control features in the machine.

- Supports the MTConnect standard to help you extract data from your machine, enabling you to assess and optimise its operation.

- A 15.6-inch screen makes the machine easy to operate, while GrabCAD Print and Insight software are included to simplify, speed up and improve your builds.

Keeps printing, no matter what

Four extruders mean extra redundancy. If there is a blockage in a print head, the machine can automatically sense what is happening, park it, switch to another head and carry on printing, with no user intervention needed. You can also choose the type of material assigned to each head, so you could have one for a model material and three for support if your application requires it, or any other combination that works for your build.

Increased material spools

Four large spools of material can be loaded in the machine at once. Each newly designed spool holds 4100cc of material, allowing for much longer unattended printing than with other machines. Chips are mounted in a handle and tethered to the spool for increased convenience. Material driers keep the material temperature and moisture levels uniform, helping increase part quality yet further.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

600 x 600 x 800 mm

-

SYSTEM SIZE

203.2 x 162.6 x 236.2; 1360 kg

-

MATERIAL CAPACITY

16,400 cc total

-

MATERIAL DELIVERY

Four material spool bays feeding four extruders

-

ACCURACY

+/- .067 mm or +/- .0015 mm per mm, whichever is greater

-

SOFTWARE

GrabCAD Print, GrabCAD Print Pro, Insight, MTConnect enabled

-

NOISE

<65 dBA when idle and in operation

-

CAMERAS

Front-mounted showing extruder level and rear-mounted showing full chamber view

MATERIALS

Four material spool bays feed four extruders. You can mix-and-match model or support with independently controlled material dryers included.