FDM technology highlights

FDM printing technology is one of the longest-used 3D printing processes. As is common with other rapid production systems, FDM 3D printers also read data from STL files, which they then convert into reference points for reproducing the original design within the printer’s build envelope.

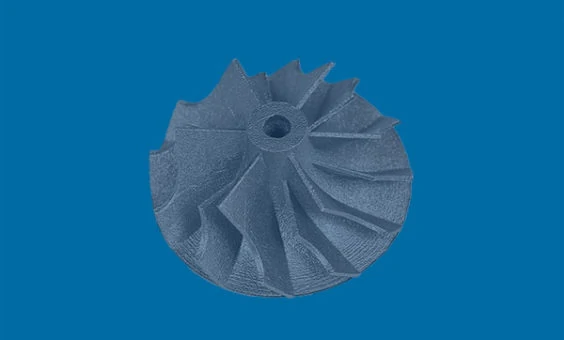

To create parts via FDM printing, the printer heats a continuous thread of thermoplastic filament, of which a fine bead is extruded through a heated tip. This is laid down on the print bed on extrusion. When the first layer is complete, the bed steps down and the process repeats itself, thus building up parts layer by layer. Each layer can be as fine as just 0.127mm (0.005in).

In addition to this, our included print software gives users unrivalled flexibility. The software that ships with our FDM printers allows the user to control various aspects of the printing process. This includes the density of the fill inside the printed model, with options for solid, sparse and low density depending on its final use scenario.

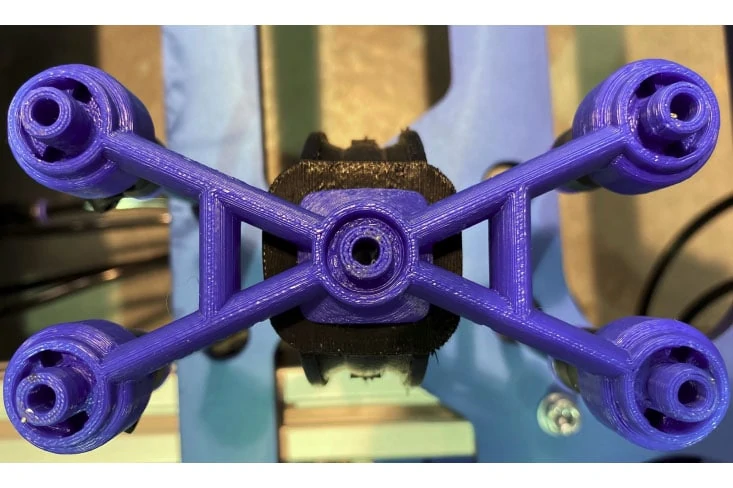

Complex structures can be produced using FDM with the help of support materials. Down-facing surfaces are supported during the print process by this support material. This can be then be jetted off or dissolved on completion of the print, leaving behind the required model.

The benefits of FDM printing

- FDM parts are strong and dimensionally stable, therefore they are able to maintain their accuracy and material properties over time.

- Parts can be built using ISO materials when used for medical applications and for contact with food. Compatible UL V0 materials are suitable for use in aircraft parts.

- The rigid material used in the Fused Deposition Modelling process means parts can be built with few supporting structures helping to minimise costs.

- With compact FDM 3D printer options, easy use and maintenance, they are ideally suited to office, educational and small business environments.

CASE STUDY: LOW VOLUME PRODUCTION

Form Automation

This robotics company relies on the Stratasys F370 3D printer to quickly and cost-effectively produce replacement end-of-arm tools for its network of robots.

Where accuracy, durability and heat tolerance are key considerations, look to FDM. The choice of materials makes it one of the most flexible 3D options.

Mark Tyrtania, Sales Director, Laser Lines