FDM 3D Printers: UltiMaker S3

Find out more about FDM 3D Printers

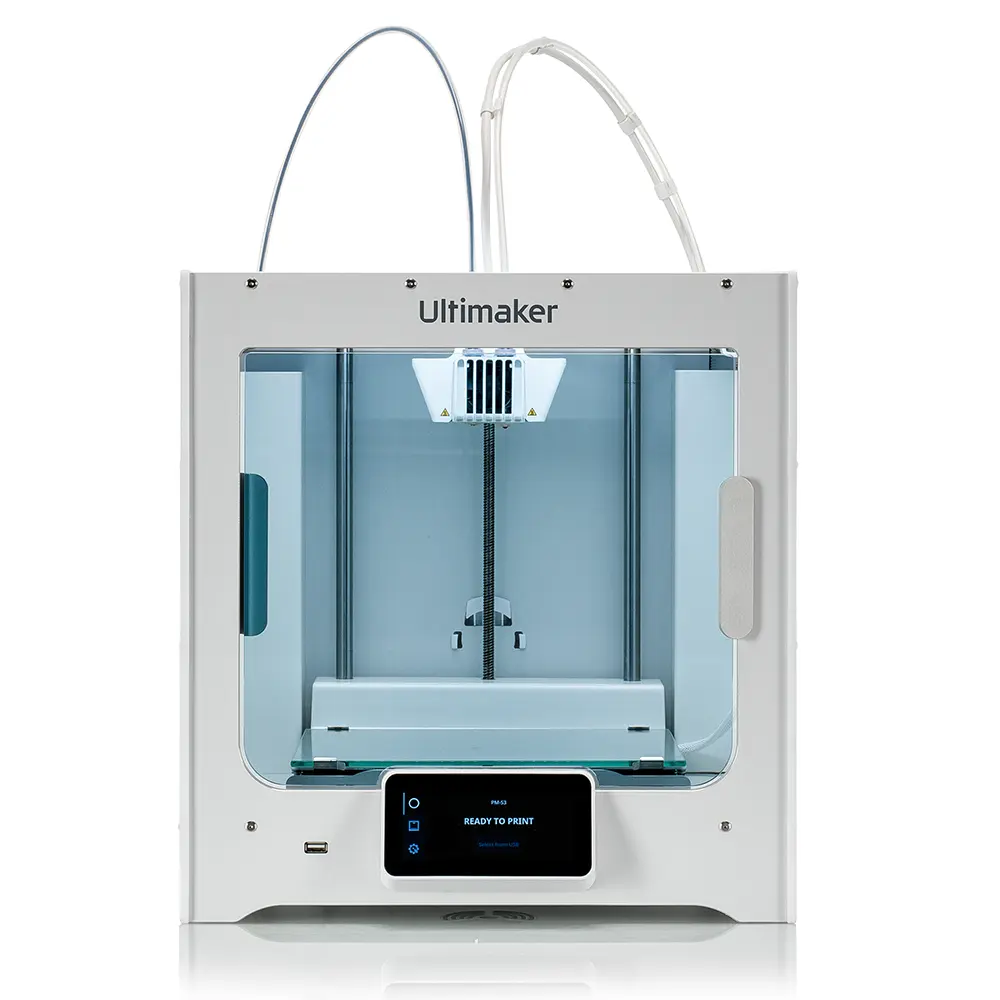

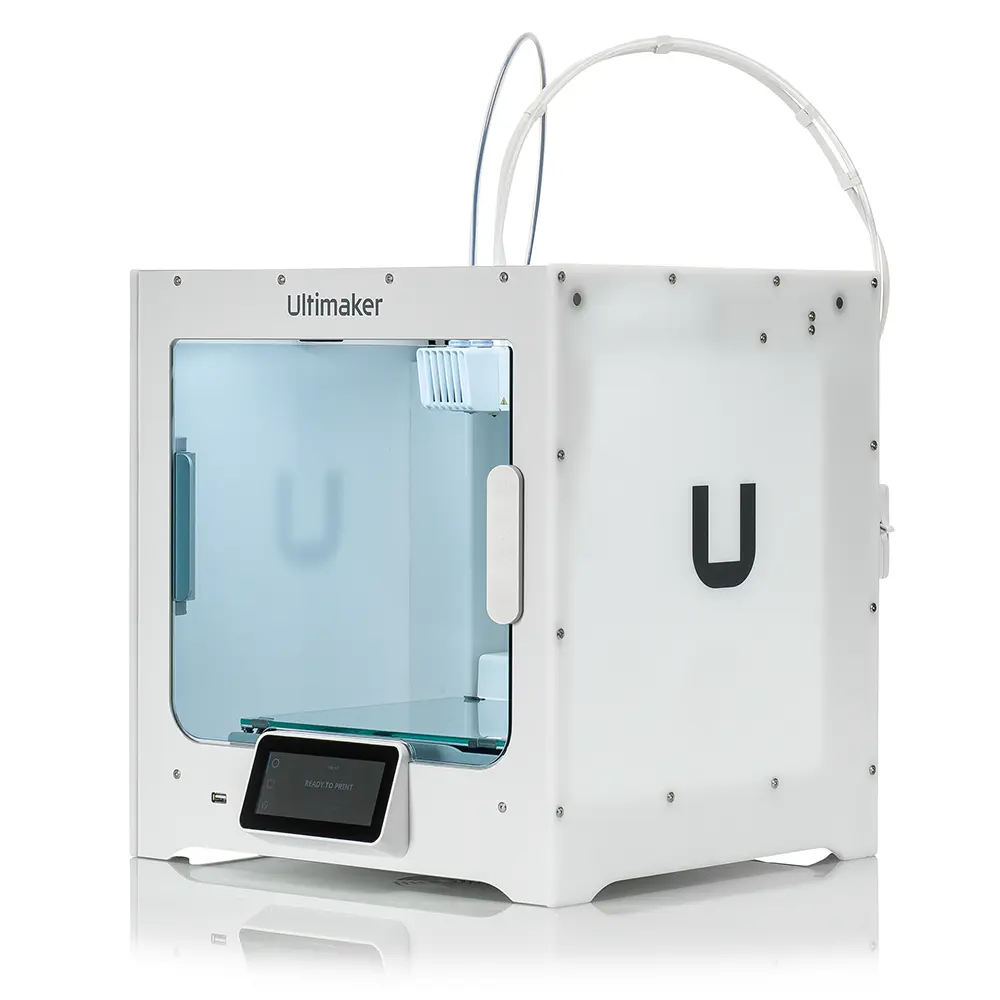

UltiMaker S3

A desktop 3D printer with dual extruders, the UltiMaker S3 is reliable and resilient enough to print with carbon fibre and glass, along with materials such as ABS, PETG and Tough PLA. This compact machine has many innovations designed to improve the quality of parts it produces, including active levelling, which removes the need for fiddly manual levelling and lets you print unattended. The UltiMaker S3 is simple to operate thanks to an intuitive touchscreen interface, and features a flow sensor to inform you when the filament has run out, making your life easier. The S3 has been designed to be so simple to use, it can be put to work by a novice after just 30 minutes of introductory information.

Key features

- Dual extrusion print head has an automatic lifting system for the print nozzles

- Print cores are swappable, enabling switching between standard and abrasive composite materials in addition to breakaway or soluble support.

- Heated, glass build plate together with accurate stepper drivers and a stiff build plate help to improve part quality

- Maximum build volume: 230 x 190 x 200mm

- Simple, 4.7-inch touchscreen provides intuitive menus to control the machine and show a preview of your print

- A flow sensor alerts you when the machine runs out of filament

- You can print via the cloud, connecting to the machine through Wi-Fi and Ethernet. Or use the USB port to transfer your designs

Over 190 materials

This flexible machine enables you to use virtually any third-party filament, along with those made by UltiMaker, with over 190 verified parameters available to download from the UltiMaker Marketplace. In addition to multiple plastic and carbon fibre options, an optional metal expansion kit lets you print ‘green’ stainless-steel parts with a hassle-free de-bind and sintering service

PVA removal station

Increase the UltiMaker S3’s productivity further by investing in the UltiMaker PVA Removal Station. This machine reduces the time needed to process a part by circulating water in a tank at a high speed to remove PVA support material as fast as possible. No chemicals are required, simply tap water.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

230 x 190 x 200 mm

-

SYSTEM SIZE

394 x 489 x 637 mm; 14.4 kg

-

PRINT HEAD

Dual-extrusion print head with a unique auto-nozzle lifting system and swappable print cores

-

XYZ RESOLUTION

6.9, 6.9, 2.5 micron

-

BUILD SPEED

< 24 mm³/s

-

BUILD PLATE

Heated glass build plate (20 - 140 °C)