Polyjet 3D Printers: Stratasys J850 Prime/FabriX

Find out more about Polyjet 3D Printers

Stratasys J850 Prime/FabriX

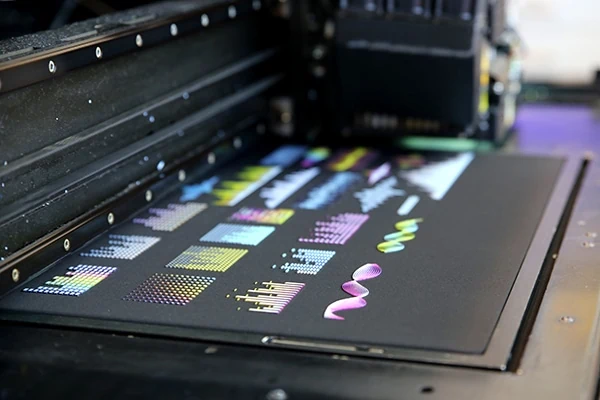

The FabriX Innovation Kit, comprising hardware, materials and software upgrades, is a state-of-the-art option specifically for the J850™ Prime 3D printer. This new solution is perfect for designers looking to 3D print onto fabric and flexible substrates with applications in haute couture, education, consumer goods, embedded electronics, concept car and automotive industries. For users already running a J850, the kit can be taken as an upgrade, extending the ultra-realistic CMF (Color-Material-Finish) capabilities of the printer. The FabriX innovation kit transforms the J850 Prime into an end-to-end hybrid system for printing both 3D model parts and 3D printing on flexible, flat substrates, such as fabric, carbon fibre, flexible polymers, mylar, netting, canvas and more. The ultimate solution for design and concept 3D printing with a super simple workflow that is easily implemented using Stratasys’ GrabCAD™ Print software.

Key features

- Fabric mounting jig (0.2-2.5mm thickness)

- Automatic fabric thickness calibration

- Flexible Material Printing on Fabric

- UV light illumination control during print process

- Netting-Fabric Insert

- Fabric Analyzer Wizard

Greater opportunities

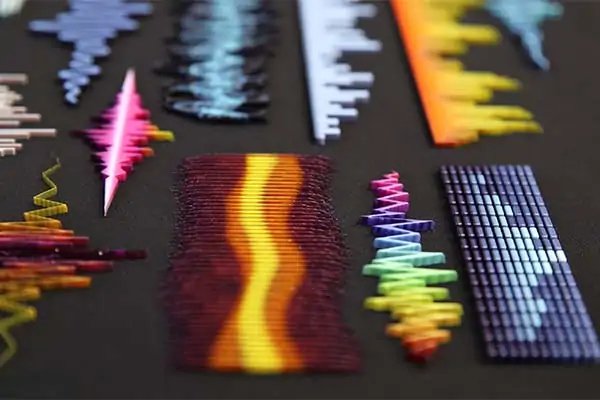

Providing an unlimited number of digital materials including over 600,000 colours, Pantone® Validated palettes and translucent colour tints, the J850 can also print flexible tactile materials in a variety of textures. Coupled with the FabriX Innovation kit, new and existing J850 Prime users can take their designs and prototypes to a level that has not been previously possible.

Explore new applications

The FabriX™ Innovation Kit for the J850™ Prime allows you to test different designs for applications containing meshed materials, functional apparel prototypes and even filtration systems visualization. Long-standing conceptions regarding direct 3D printing onto fabrics and flexible substrates has changed with wearable electronics now a reality. Another area for innovative design is proving to be car interiors. A variety of textures and patterns is now available truly opening up the possibilities for product designers.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

490 x 390 x 200 mm; 460 x 360 x 200mm in FabriX mode

-

SYSTEM SIZE

1400 x 1260 x 1100 mm, 430 kg

-

ACCURACY

Typically, under 100 mm – ±100μ; above 100 mm – ±200μ or ± 0.06% of part length

-

MATERIAL CABINET SIZE & WEIGHT

1119 x 656 x 637 mm, 153 kg

-

SOFTWARE

GrabCAD Print

-

LAYER THICKNESS

Horizontal build layers down to 14 microns (55 microns in Super High Speed mode). 27 microns running FabriX.

-

WORKSTATION COMPATIBILITY

Windows 10

-

NETWORK CONNECTIVITY

LAN - TCP/IP

-

FABRIC SIZE HANDLING

Min. 560 x 460mm

-

FABRIC THICKNESS

0.2 - 2.5mm

MATERIALS

MODEL MATERIAL

Vero family - Opaque materials and neutral shades

DIGITAL MATERIAL

Unlimited number of digital materials

Over 600,000 colours and Pantone Validated palettes

Translucent colour tints

Flexible tactile materials in a variety of textures and colours