FDM 3D Printers: UltiMaker Method XL

Find out more about FDM 3D Printers

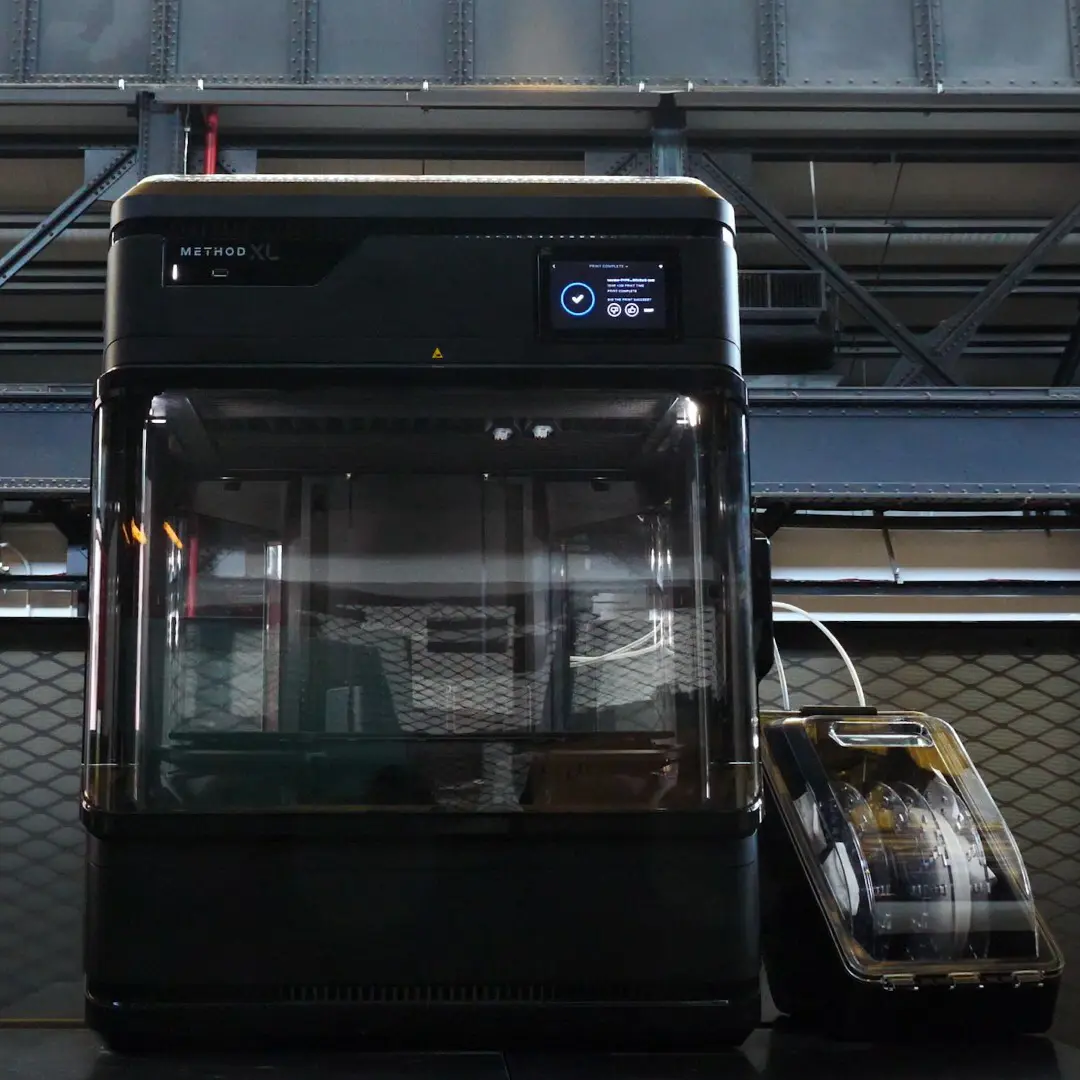

UltiMaker Method XL

When size matters, turn to the UltiMaker Method XL, the 3D printer with the largest build envelope in the Method line at 305 x 305 x 320mm. The machine has both a heated chamber and a heated build plate, helping it to produce better results when using materials such as ABS-R and ABS carbon fibre. With a dimensional accuracy of ± 0.2 mm, the machine sits firmly in the professional category, creating superb end-use parts and prototypes. MakerBot CloudPrint™ software allows for remote monitoring, while a moisture-controlled material case improves the performance of professional-grade materials even further.

Key Features

- Actively heated chamber: Capable of reaching 100 degrees, the machine uses Variable Environmental Controlled Temperature (VECT) technology to control the print environment and ensure it is evenly heated. This creates parts that are twice as strong on the Z-axis and twice as accurate.

- Flexible, heated build plate: Reaching temperatures up to 105 degrees, the heated build plate creates better adhesion and helps with overall temperature control for more accurate parts.

- HEPA and carbon filter: A dual activated carbon and HEPA filter is inside the UltiMaker Method XL, removing any unpleasant smells and making the machine pleasant to use in an office environment.

- MakerBot CloudPrint™ : This software makes it straightforward to import CAD files and arrange your parts. Pre-set printer modes are available, plus you can monitor jobs via a live camera from anywhere in the world.

External material case

An external material case makes it easy to load materials and is moisture-controlled to get the peak performance from your materials. Access a wide range of industry-standard materials, including ABS carbon fibre, Nylon 12 carbon fibre, ABS-R and PC-ABS among many others. For even more choice, upgrade to a Labs Gen 2 experimental extruder to enable your machine to use third-party materials.

RapidRinse support

For the fastest support removal that maintains the part’s surface finish, use RapidRinse support material with ABS-R parts. With this, after designing any geometry you want, in any orientation, the support structure can be dissolved in tap water in a few minutes.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

305 x 305 x 320 mm (dual extrusion)

-

SYSTEM SIZE

Printer: W 655 x D 565 x H 815 mm; 56.5 kg

-

HEATED CHAMBER MAX TEMPERATURE

100 °C

-

COMPATIBLE FILAMENT DIAMETER

1.75 mm

-

MAXIMUM POWER OUTPUT

1400 W

-

LAYER RESOLUTION

0.4 mm nozzle: 100 - 400 micron

-

OPERATING SOUND

57.1 +/- 3 dB

-

DISPLAY

5-inch touchscreen

-

SOFTWARE INCLUDED

MakerBot CloudPrint™

MATERIALS

MODEL MATERIAL

Low temperature polymers such as Tough PLA, Nylon and PETG

High temperature polymers such as ABS-R, ABS, ASA and PC-ABS

Nylon 6 Carbon Fibre, Nylon 12 Carbon Fibre & ABS Carbon Fibre

PVA, RapidRinse and SR-30 support materials

Makerbot PLA

Makerbot Tough PLA

Makerbot PETG

Makerbot Nylon

Makerbot Nylon 6 Carbon Fibre

Makerbot Nylon 12 Carbon Fibre

Makerbot ABS-CF

Makerbot ABS-R

Makerbot PC-ABS

Makerbot PC-ABS FR

Makerbot ASA

Makerbot PVA

SR-30

Rapid Rinse Soluble Support