SLA 3D Printers: Stratasys Neo450

Find out more about SLA 3D Printers

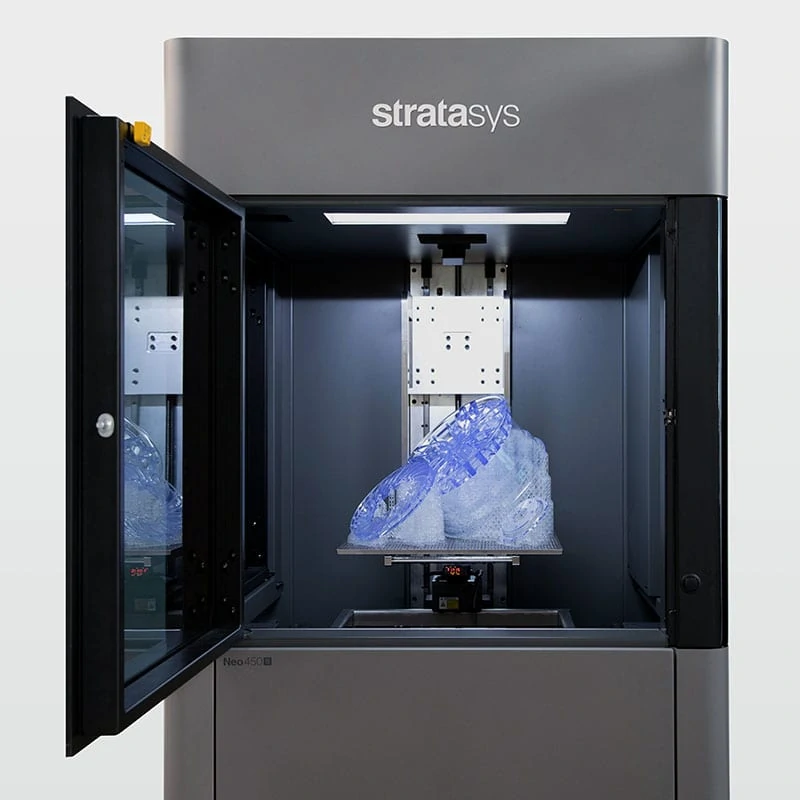

Stratasys Neo450

Accuracy. Repeatability. Strength. If you need these qualities from the parts you manufacture, the Neo 450e and 450s are perfect for creating small to medium parts. For rapid tooling, prototypes and master patterns, the Neo450 range offers industrial-grade parts using its a large 450 x 450 x 400 mm build platform. An open material system lets you use any 355mm SL resins, giving you freedom to choose the material that suits your application best. Designed and engineered in the UK by the pioneers of large format Stereolithography (SLA), the Neo450e and Neo450s are smaller, more compact alternatives to the Neo800 for users that do not need such a large build volume.

Key features

- Produce small and medium-sized parts using the 450 x 450 x 400 mm build platform.

- Open material platform frees you from the usual restrictions, offering compatibility with all 355nm SL resins.

- Stable, reliable system that excels in high-pressure environments such as service bureaus and in Formula One.

- Exceptional part sidewall quality reduces finishing time by up to 50%.

- Inbuilt camera helps you stay updated with the status of your builds.

- Titanium software integrates with a variety of Industry 4.0 tools.

Neo450e vs Neo450s

There are two different Neo450 machines available designed to suit different budgets and applications. Choose the affordable Neo 450e for a dependable, reliable additive manufacturing machine that can print non-stop. Upgrade to the Neo 450s for parts produced up to 40% faster, with both standard definition and high-definition modes to choose from. For those that need an an even larger build platform, the Neo 800 is perfect for large parts or to produce multiple, smaller parts in one build.

Titanium software

Every Neo printer comes with powerful Titanium software that lets you trace each part back to a particular build and see its parameters, along with reporting tools to help you demonstrate the machine’s value in meeting your company’s business objectives. In addition to a scheduled start feature, Titanium offers build validation, a time estimator and a material usage estimator so you can plan jobs effectively and ensure their success before you begin the build.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

450 x 450 x 400 mm

-

SYSTEM SIZE

1050 × 1225 × 1900 mm, 600 kg

-

LASER

Neo450e: 1 Watt; Neo450s: 2 Watt

-

BEAM FOCUS

Neo450e: Dynamic; Neo450s: Dynamic & Variable

-

BEAM SIZE

Neo450e: 250 μm; Neo450s: 80 to 750 μm

-

LAYER RESOLUTION

50 to 200 μm

CASE STUDY: AUTOMOTIVE

McLaren Racing — Advantage on the track with Stratasys Neo800

Stratasys’ Neo800 stereolithography 3D printers are enabling McLaren Racing to make up to 9,000 parts per...

MATERIALS

An open material system means users can use any 355nm SL resin, allowing the freedom of material selection and none of the usual parameter constraints.

In addition, the Neo 3D printers can run these technically advanced stereolithography materials: