How Does SLA Printing Work?

A thin layer of liquid polymer is spread over the printer platform, ensuring a consistent thickness. A UV laser then draws the outlines of the model onto the resin. As the resin is UV sensitive, the areas touched by the laser are instantly cured and hardened. The areas untouched by the laser remain liquid. The model is then lowered a fraction so that this process can be repeated and a new layer added, until the full model is complete. Any remaining liquid polymer can then be drained away and reused for future models. The finished print must then be finished off, any support structures removed, surfaces smoothened and surfaces spray painted, if desired.

SLA 3D printers

Stratasys Neo

The Stratasys Neo800 and Stratasys Neo450 3D printers are proven, reliable machines that take large-format SLA 3D printing to the next level. With an open choice in resins, low service requirements and accurate builds, they are an excellent choice for those that need parts with an exceptional surface finish.

Further Information

For further information, explore our stereolithography 3D printer range. Unsure of exactly what it is you’re looking for or which the best resin 3D printer is for you? Contact one of our friendly and knowledgeable team today to discuss the workings of SLA printing and the potential benefits to your business.

Advantages of SLA Printing

The SLA process is flexible, clean and fast, helping to reduce both costs and your carbon footprint by keeping waste to a minimum. All of the required material transfers to the part, with any excess re-used in subsequent layers.

The only additional parts to consider are supports, common to most 3D printing technologies, to be broken away when the job is complete. These are calculated and built into the design automatically by the management software.

With a wide range of resins to choose from, and the ability to mix your own colours, SLA offers huge flexibility and range of design options. With fewer moving parts inside the build chamber, SLA printers can maximise the amount of space they give over to part production, reducing the overall size of the printer and making it easier to accommodate.

This ability to produce larger parts also helps SLA-produced tools to maintain structural integrity as it doesn’t require multiple smaller parts to be fused. For this reason, among others, the SLA printing process is renowned for producing hard-wearing, long-lasting, production-ready parts.

SLA benefits

- Stereolithography allows for the production of prototype parts in just a few hours, accelerating the development process and allowing for a greater number of iterations in any given time.

- While sizes of the X and Y planes will be determined by the dimensions of the printer, the maximum height of the Z plane will often exceed that which is possible with other 3D printing technologies in printers of comparable size.

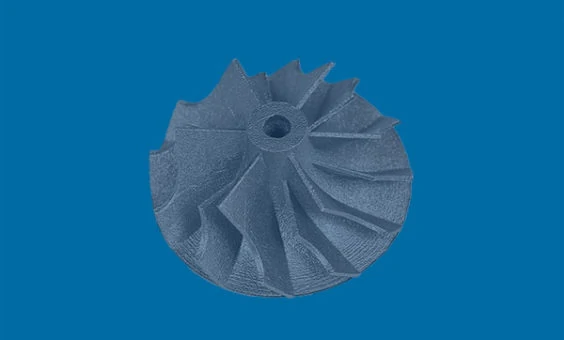

- The liquid resin used in stereolithography is strong and resilient when fused, allowing SLA printers to produce final use parts and tools, as well as patterns for metal casting.

I wanted to let you know how impressed we have been with our new Neo 3D printers.

James Colgate, Williams Racing Operations Director