Software: Materialise e-Stage

Find out more about Software

Materialise e-Stage

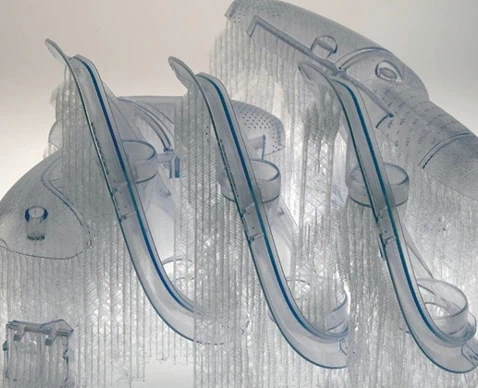

Materialise e-Stage specifically focuses on automating and optimizing the process of creating support structures for 3D printed parts. These support structures are essential for complex or overhanging geometries, helping to ensure successful and accurate 3D printing.

Key Features

- Streamline data preparation. Decrease your time spent on support design by up to 90% using automated software for stereolithography (SLA)

- Reduce time spent on support removal. Cut the time spent on support removal by up to 50% with e-Stage’s needle-thin contact points and a grid structure.

- Lower resin consumption. Lower your part’s resin consumption using gusset parameters and recuperate excess raw material thanks to e-Stage’s open structures and excellent drainage capabilities.

- Simplify finishing for parts. Reduce the time spent finishing a part, as e-Stage only generates support structures where needed. Furthermore, the unique needle shape minimizes surface damage, requiring less repair work.

Reduce time and material consumption

The software utilizes advanced algorithms to generate support structures that minimize material usage and print time while maintaining the structural integrity of the printed object. This optimization is crucial for efficiency and cost-effectiveness in the additive manufacturing workflow.

Automate support generation

The Materialise e-Stage automatically generates support structures for the part and reinforces all the necessary surfaces and support connections of tall, thin parts. The software also accounts for the force of the machines re-coater during the production process.