FDM 3D Printers: UltiMaker Method X

Find out more about FDM 3D Printers

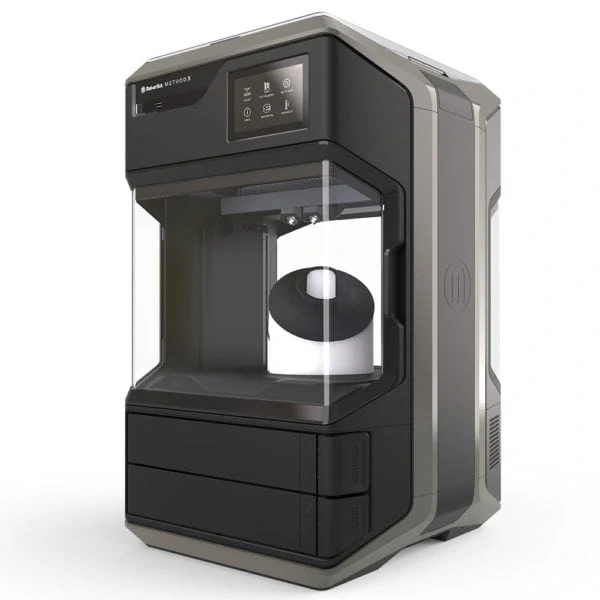

UltiMaker Method X

The UltiMaker Method X is perfect for engineers making end-use parts, manufacturing tools or functional prototypes. Able to print real, production-grade ABS-R with a 100°C temperature-controlled build chamber, the quality of the parts you get from this machine outstrip those from competitors that use modified ABS material. Parts from the UltiMaker Method X are the best you can get at this price point, and they are produced in a fraction of time it takes with traditional techniques. The machine utilises either RapidRinse or SR-30 soluble support material for greater geometry and design freedom. The Method X takes all the best elements of its predecessor and further improves on them, offering engineers best in class accuracy and durability.

Key features

- Prints using true, engineering-grade ABS-R, producing tools that will last, prototypes that are dimensionally accurate and end-use parts

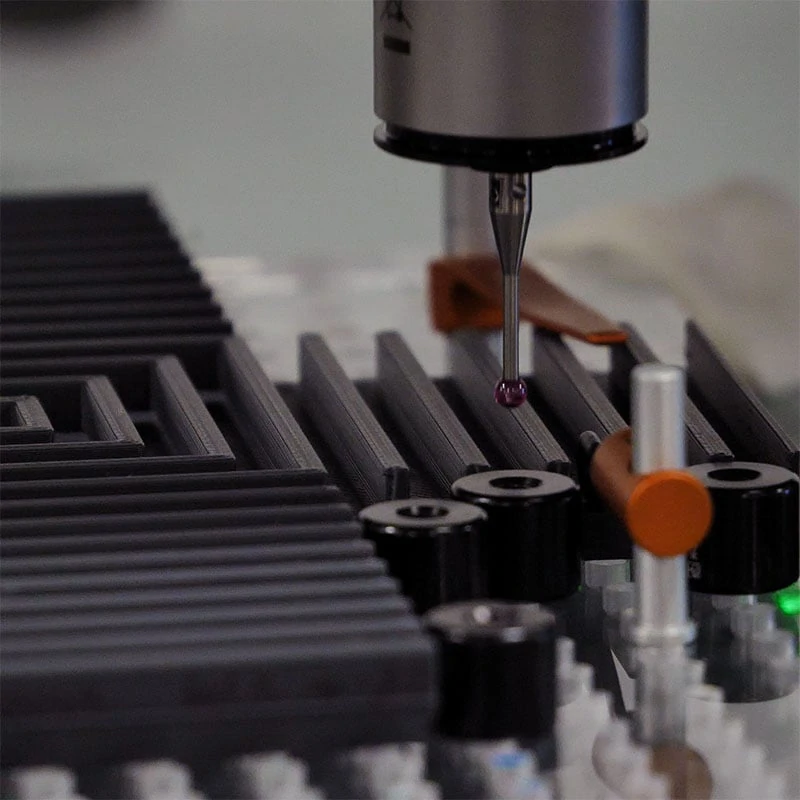

- Finished parts have a dimensional accuracy of ± 0.2mm

- Twice as fast at printing than its leading competitors

- A 100-degree Celsius heated build chamber for exceptional results

- Utilise RapidRinse, SR-30 soluble support or PVA support materials

- 21 onboard sensors, Wi-Fi and a 5-inch colour touchscreen make this an easy machine to operate and maintain

- Compatible with 25 CAD file types

- Over 300,000 hours of reliability testing have been undertaken

True ABS printing

The MakerBot ABS-R material used on the UltiMaker X can withstand 15°C higher temperatures than modified ABS materials that other desktop 3D printers use. It is also 26% more rigid and up to 12% stronger than those materials. The RapidRinse or SR-30 soluble support material, combined with ABS-R and the 100°C chamber results in strong, complex parts with a superior surface finish.

Strong foundations

The improved Method X has many of the same benefits as the original Method, such as an ultra-rigid metal frame, dual extruders and dry-sealed material bays. It is compatible with Solidworks, Autodesk Fusion 360 and Inventor.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

Single Extrusion: 190 x 190 x 196 mm; Dual Extrusion: 152 x 190 x 196 mm

-

SYSTEM SIZE

437 x 413 x 649 mm, 29.5 kg

-

DIMENSIONAL ACCURACY

± 0.2mm

-

LAYER RESOLUTION

Maximum Capability: 20 - 400 micron

-

SODTWARE INCLUDED

MakerBot CloudPrint™