CASE STUDY: AUTOMOTIVE

Formula Student – Somos® PerFORM Tooling and Composite Layup

Case study of use of Stratasys NEO - Written by Maria Rubia, OBR19

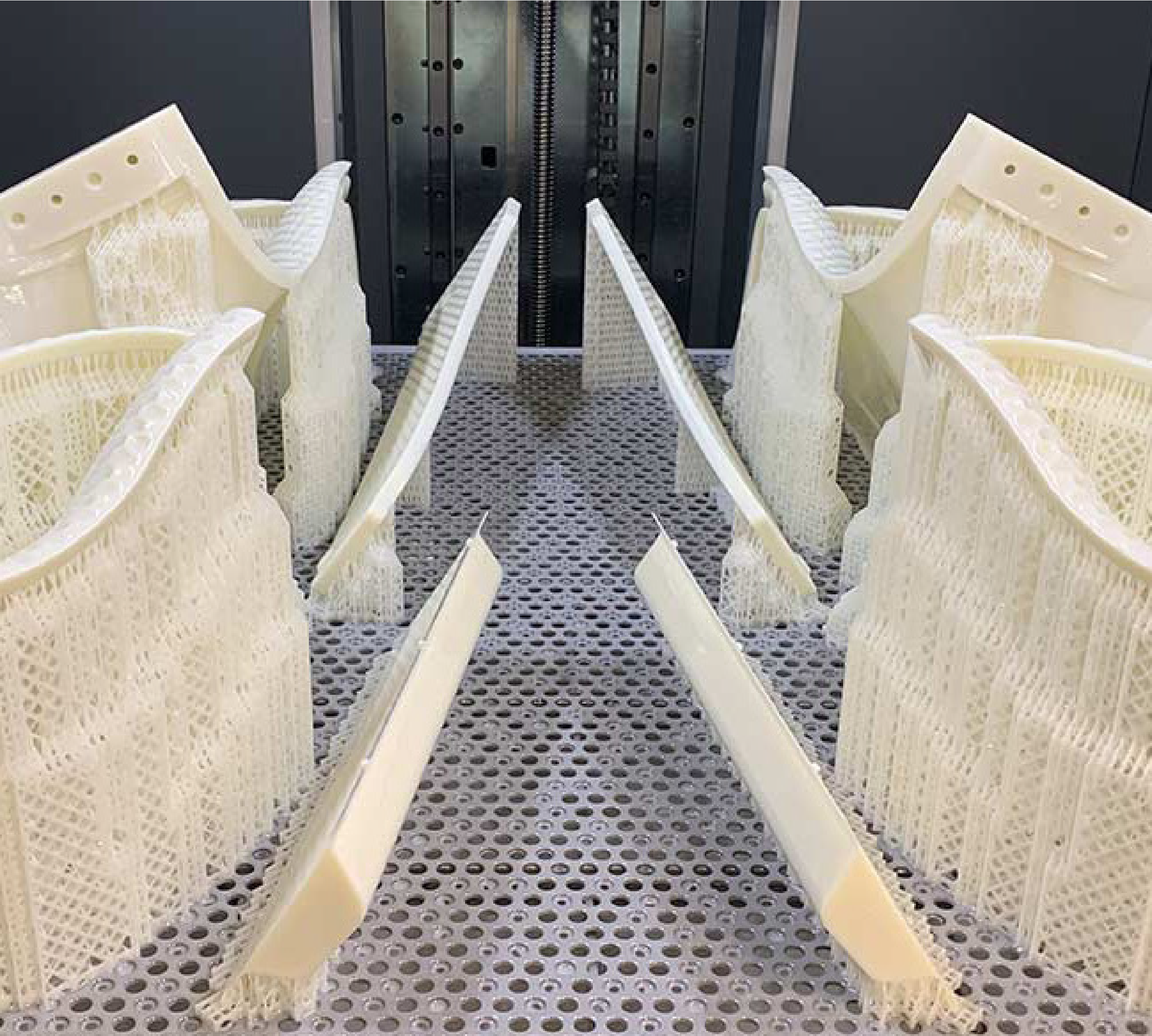

McLaren Racing — Advantage on the track with Stratasys Neo800

Stratasys’ Neo800 stereolithography 3D printers are enabling McLaren Racing to make up to 9,000 parts per year — from full-size...

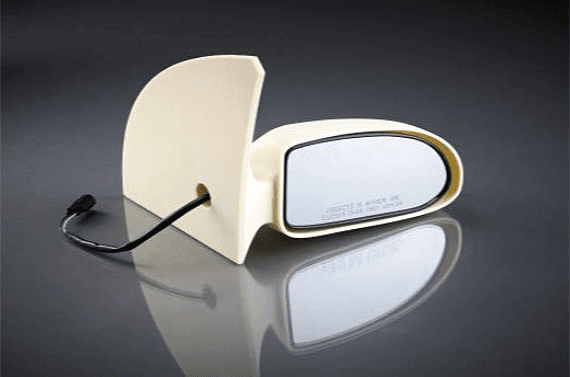

1966 Chevy Impala restored with an Xact Metal machine

In 1980, a young car enthusiast named Tomme acquired a 1966 Chevrolet Impala after it had been damaged in a fire. The interior was ruined, and the dashboard had taken a beating, but the car still had life in it, and Tomme was determined to restore...

Holly Mason and Ten Tenths receive superb support from Laser Lines

Ten Tenths is dedicated to keeping Nick Mason’s collection of road and competition cars in peak operating condition. The collection, that numbers around 35-40 at any time, spans pre-war racers right up to today’s hybrid performance road cars. All are...

Using a bureau saves time for automotive jigs and fixtures

Roaring Forties specialise in manufacturing Ford GT40 replicas & have been using FDM parts sourced through a bureau service for years. Roaring Forties buy FDM jigs & fixtures as it decreases lead times & saves on expensive machining time. Ford...