CASE STUDY: EDUCATION

Nishuane Elementary

How MakerBot 3D printers helped introduce 7-year old schoolchildren to the wonders of additive manufacturing.

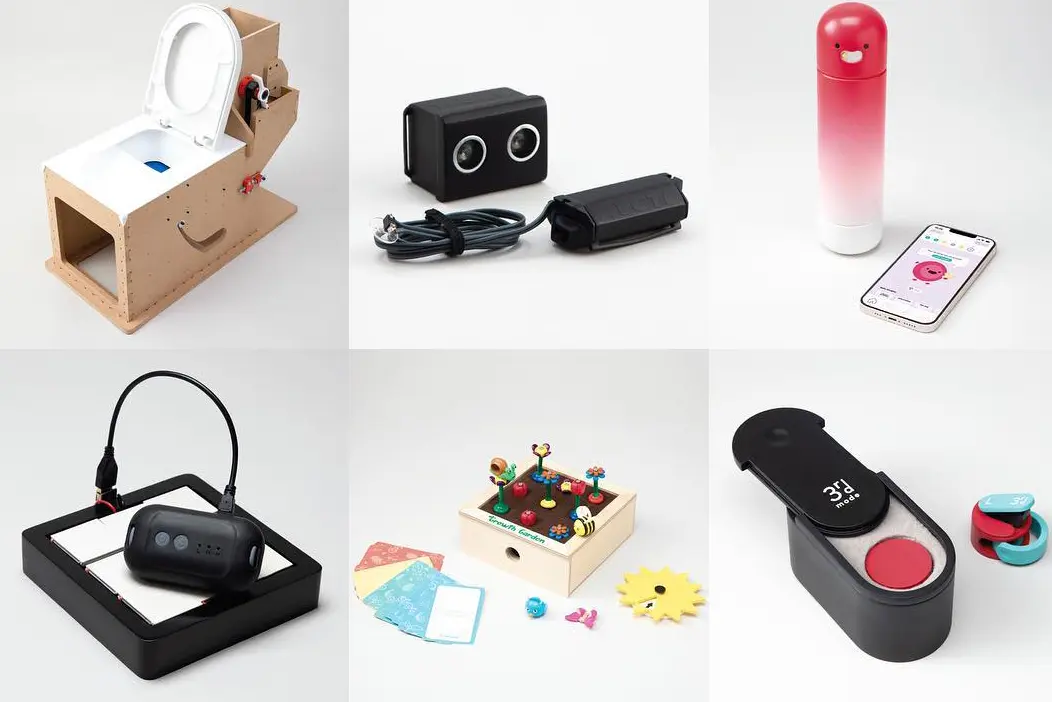

CASE STUDY: CONSUMER PRODUCTS

Synergy

Synergy is a product development company in Israel and has used a Stratasys J750 to produce photorealistic prototypes.

CASE STUDY: AUTOMOTIVE

Using a bureau saves time for automotive jigs and fixtures

Roaring Forties specialise in manufacturing Ford GT40 replicas & have been using FDM parts sourced through a bureau service for years. Roaring Forties buy FDM jigs & fixtures as it decreases lead times & saves on expensive...

CASE STUDY: AEROSPACE

FDM Bureau Builds 3D Printed Parts for Recreational Aviation

Recreational aeroplane manufacturer ICON is working on their products becoming as popular as motorcycles & powerboats. ICON have used a FDM service bureau to not only save time & money but design end use parts for their latest A5...

CASE STUDY: DEFENCE

Lockheed Martin 3D Prints a Large Prototype Fuel Tank

Lockheed Martin Space Systems Company designs, develops & manufactures high-tech systems for civil, defence & commercial applications. In 2012 Lockheed Martin SSC were working on a new project to improve their satellite by...

CASE STUDY: JIGS AND FIXTURES

Peak Group delivers 3D printed ‘shop floor-ready’ parts in record time

Better designed and a faster time to the market – investing in a Fortus 360 has increased production capacity for The Peak Group by 3D printing the most high quality "impossible parts" and making incredibly substantial time...

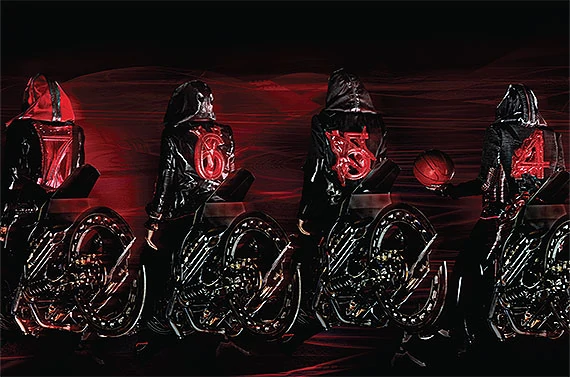

CASE STUDY: ENTERTAINMENT

Nakazato

3D Printing is revolutionising the fashion industry; Japanese designer creates a motorcycle-riding-punks-playing-basketball look for his 2014 collection of neo-futuristic sportswear.

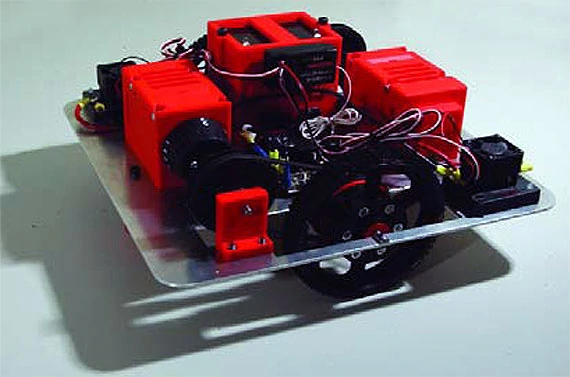

CASE STUDY: EDUCATION

Bishop Reding

The Dimension 3D Printer has taught students how to design, build, code and test their models in response to solving engineering problems. It brings together hands-on practice of using both the software and hardware and encourages...