CASE STUDY: EDUCATION

Cornell University

Owning the world’s largest collection of Franz Reueaux kinematic machines, Cornell University have replicated the models from digital files using their Dimension 3D Printer. Students can now have physical interaction with the fully...

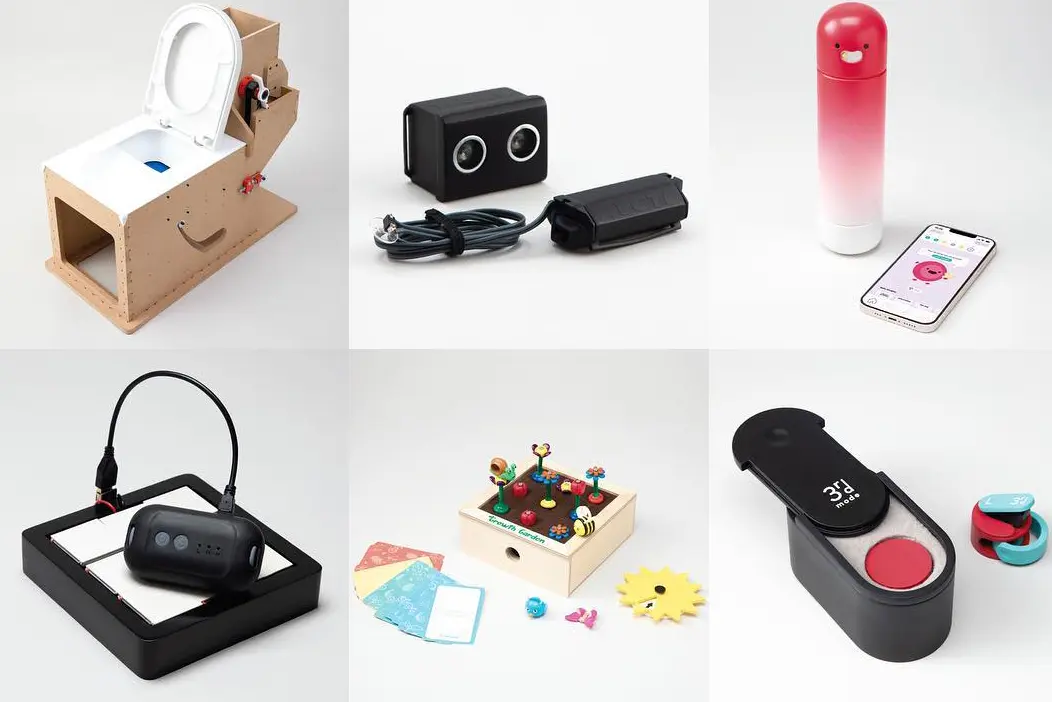

CASE STUDY: EDUCATION

Lake Zurich

Being able to print their designs required students to work through any issues which previously could be passed over as a computer model. Gauging the effect of curves, light, lines and other subtle elements now became possible with a...

CASE STUDY: EDUCATION

Royal Military College

Students can be 3d printing a ship’s hull on a Dimension 3D Printer one week and an MP3 player holder the next. RMC’s Engineering Graphics course utilises the latest 3d printing technology to enable their students to evaluate their...

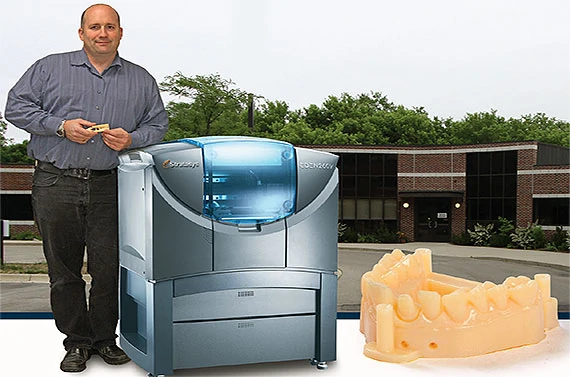

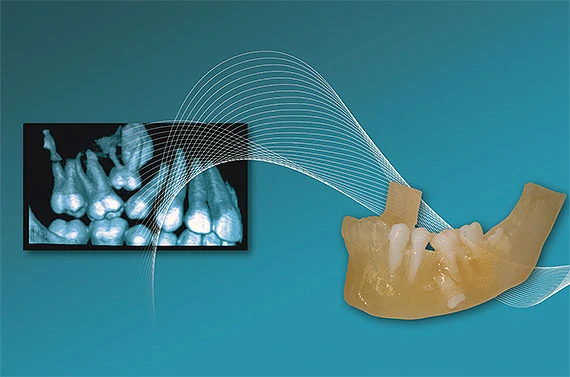

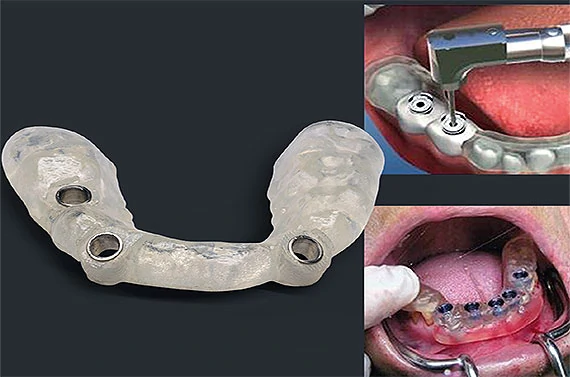

CASE STUDY: DENTAL

APEX Dental Milling Centre

Their Objet Eden 260V gave APEX the high accuracy, superior finish and shorter processing times needed for the dental parts required.

CASE STUDY: DENTAL

DentalCare

The Objet Eden260V purchased by DentalCare, enables dentists to consider different treatment plans before starting work with the patient.

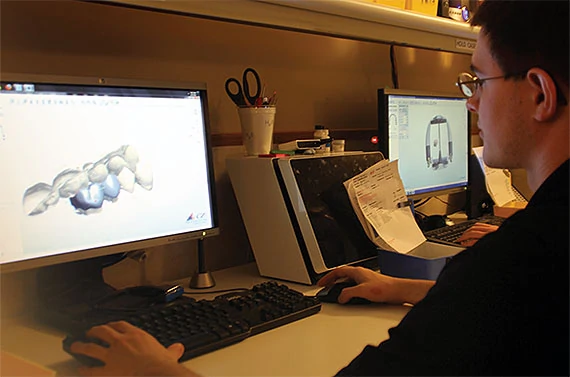

CASE STUDY: DEFENCE

EOIR Technology

Creating a camera and a mount for gun sights for tanks and fighting vehicles became a success with a Dimension 3D Printer. Previously EOIR's subcontrator's designs failed performance tests but the Dimension suceeded and then went on to...

CASE STUDY: DEFENCE

Tiberius Arms

Prior to purchasing their uPrint 3D Printer, Tiberius Arms saw a large number of design errors during the development process of their weapons. The uPrint provided a cost-effective solution.

CASE STUDY: DEFENCE

Trainer Development Flight

Producing training aids for the Air Force and Dept of Defence, TDF anticipated a return on their investment in 4 years - but it took only 18 months.