CASE STUDY: AUTOMOTIVE

Bentley Motors

3D printing enables assessment of small-scale models as well as full-size parts for assessment and testing purposes prior to production.

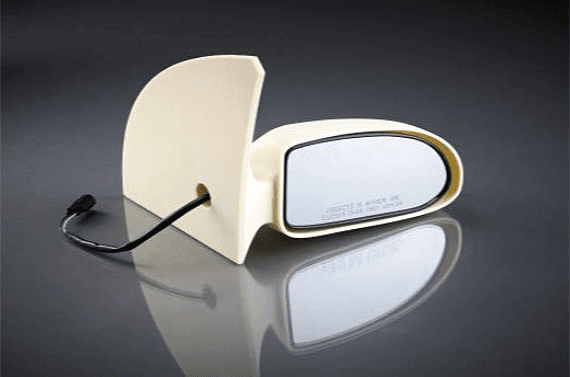

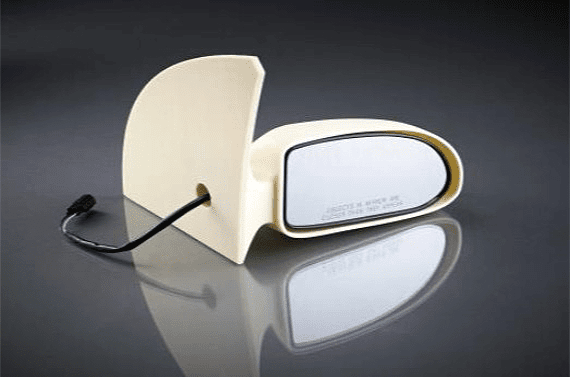

CASE STUDY: AUTOMOTIVE

BMW

Car manufacturer finds 3D printing offers significant cost advantages over metal-cutting methods including milling, turning and boring.

CASE STUDY: AUTOMOTIVE

Ducati

Developement process cut from 28 months to just 8 months as a result of Ducati using in-house 3D prints methods instead of outsourcing part buildng to service bureaus.

CASE STUDY: AUTOMOTIVE

Hyundai

3D printed instrument panel mock-up showed 27 design flaws when fitted to the cock-pit assembly. Despite being minor flaws, there was significant saving by averting the costly delays which would have resulted had these not been...

CASE STUDY: AUTOMOTIVE

Jaguar

3D printer proved its flexibility for a company encompassing the two global premium brands of Jaguar and Land Rover. Classic lines and high performance at one end and no-frills design and off-road capabilty at the other.

CASE STUDY: AUTOMOTIVE

Lamborghini

When tooling used to produce just the monocoque cost several million dollars, Lamborghini had to get the design right the first time. Their 3D printer gave them the edge.

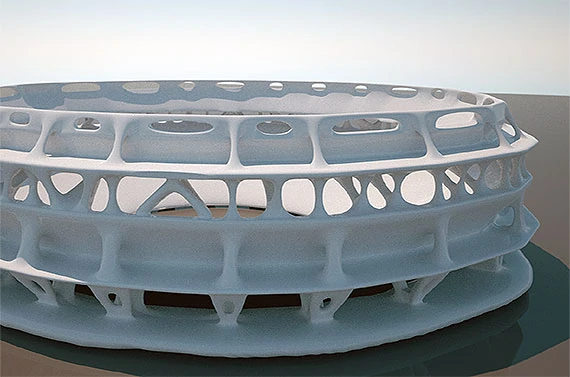

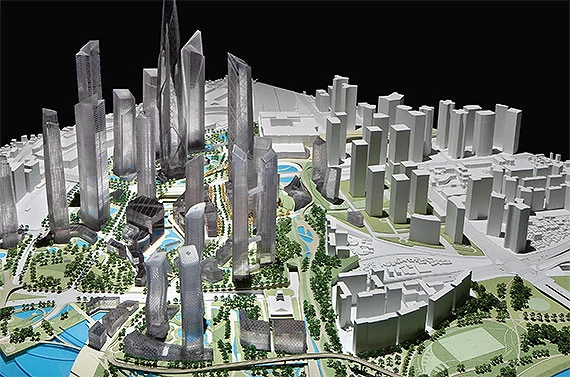

CASE STUDY:

BplusU

When designing a city for the future, complex geometry was needed. To push the boundaries the designers turned to using 3D printers.

CASE STUDY:

Camerino

Designer needs examples of his work in his hand - and not just in his mind. 3D printing gives him the answer.

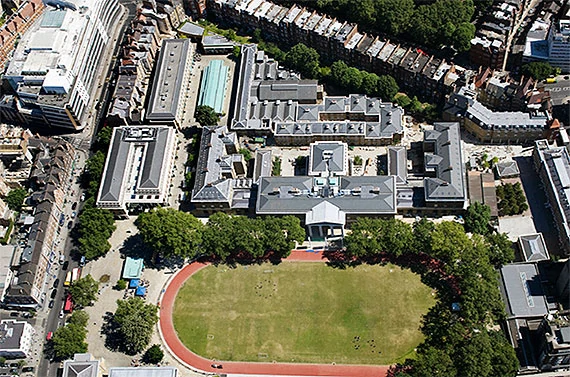

CASE STUDY: ARCHITECTURE

McCann Architecture

3D printer enables unorthodox shapes to be created - now architectual modelling company cannot imagine being without it.

CASE STUDY: ARCHITECTURE

Mitekguppen

When the city of Stockholm was 3D printed for an exhibition, the work took months instead of years. The project became the second most-visited exhibit during the year it was displayed.

CASE STUDY: ARCHITECTURE

Modelzium

Manual models precluded the use of spheres, oval shapes or thin parts but when these became necessary the designers turned to 3D printing.

CASE STUDY: ARCHITECTURE

Paul David & Partners

London architects find 3D printing models, which are available in hours and not days, significantly reduces the overall time spent working on projects.