CASE STUDY: CONSUMER PRODUCTS

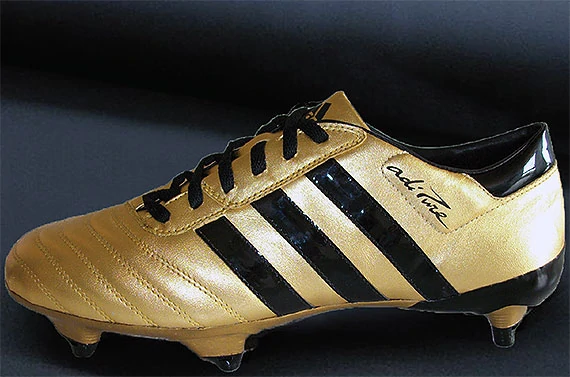

Adidas Group

Printing 3D models using multiple materials has enabled Adidas to get products evaluated and accepted in several days rather than 4-6 weeks. The demand for prototypes means their machines are running 24 hours a day.

CASE STUDY: CONSUMER PRODUCTS

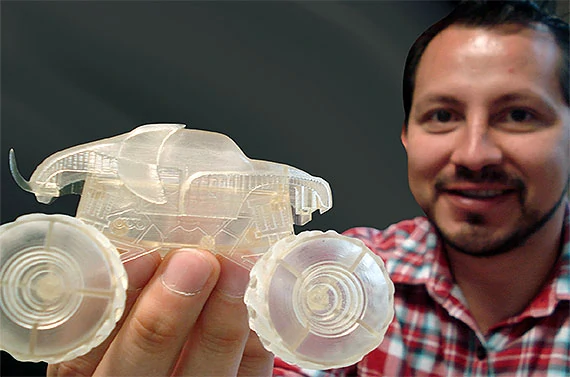

Black & Decker

The DIY product giant converted the time to produce parts from days to hours after buying their Dimension 3D Printer. Plus they have the added bonus of the designers being more productive because of reduced modelling costs.

CASE STUDY: CONSUMER PRODUCTS

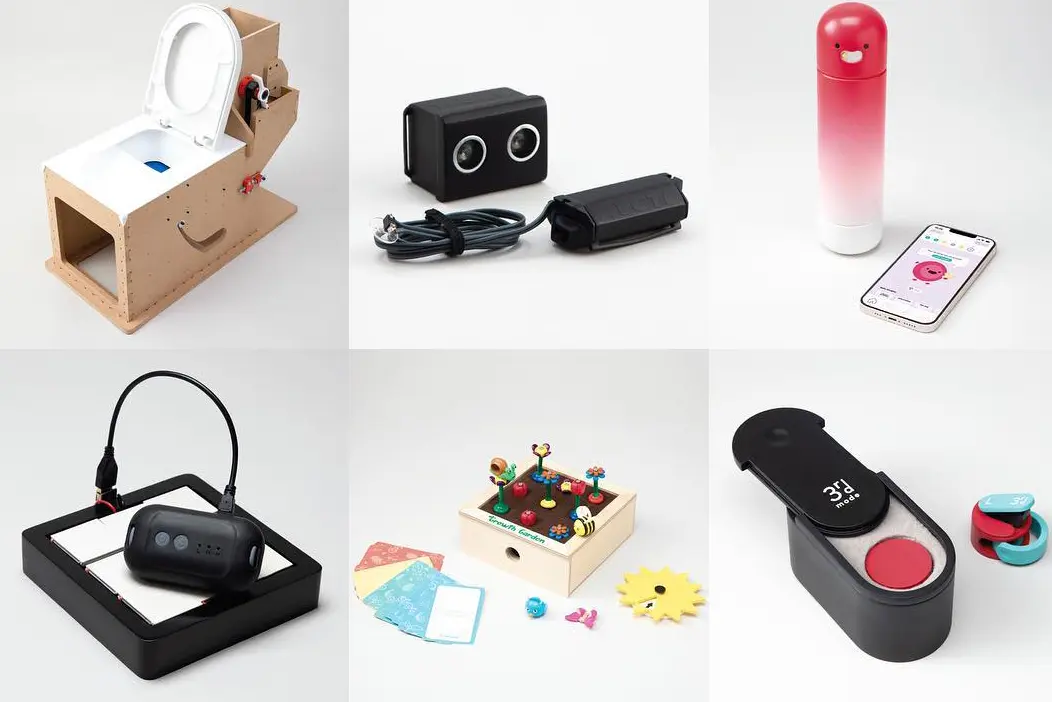

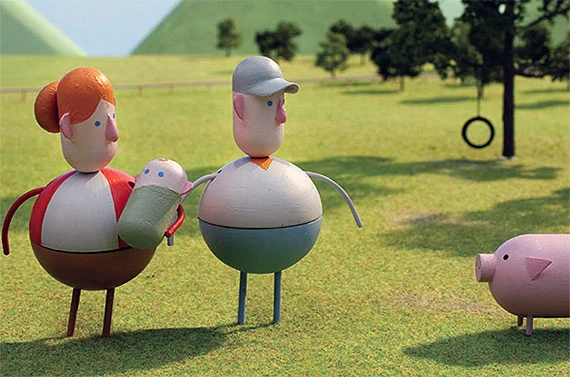

Bondy Fiesta

The benefits their Objet Eden260V gave the toy manufacturer were not just time and cost. They observed the printer improved the level of quality of both the product and the company too.

CASE STUDY: CONSUMER PRODUCTS

Cool Gear, Inc

Creator of innovative products, Cool Gear Inc, used to send drawing files abroad to get models made out of plastic or clay. The purchase of a Dimension 3D Printer changed their process completely, saving time and money.

CASE STUDY: CONSUMER PRODUCTS

Fender

After outsourcing their 3d printing requirements to services bureaus for many years, Fender brought the technology in-house to further improve their time-to-market peformance.

CASE STUDY: CONSUMER PRODUCTS

Thermos

The company invested in three Stratasys 3D Printers. These systems enable them to develop their products quickly using a mixture of clear and rubber-like materials as well as rigid ABS, thus retaining their leadership in the industry.

CASE STUDY: COMMERCIAL PRODUCTS

RedDOT

FDM prototypes succeeded for RedDOT where SLA and SLS parts had previously failed for physical testing and on evaluation units.

CASE STUDY: COMMERCIAL PRODUCTS EDUCATION

1212 Studio

Proof of Concept was needed for both an innovative illumination feature and a swinging microphone within 4 weeks for a U2 tour. Stratasys' Dimension system provided exactly the right results - on time.

CASE STUDY: COMMERCIAL PRODUCTS

Bassler

Bassler's client was so impressed with the FDM model of his product produced on a Dimension system, it was used for advertising photography instead of the real thing.

CASE STUDY: COMMERCIAL PRODUCTS

BlueSky Designs

An R&D company specializing in creating products for people with disabilities, saved more than £10,000 and 3 weeks in delivery time after installing a Stratasys Dimension 3D Printer.

CASE STUDY: COMMERCIAL PRODUCTS

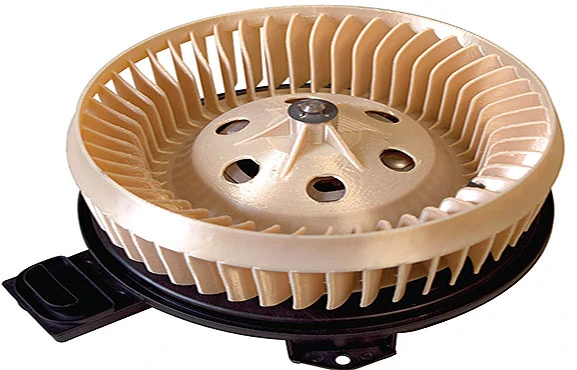

Baldor Electric Company

Designer of electric motors and transmission products bought a Dimension 3D Printer can now have an ABS part ready for testing in hours, not weeks.

CASE STUDY: ENTERTAINMENT COMMERCIAL PRODUCTS

Artem

After installing a Dimension 3D Printer, creating an animation film became infinitely easier due to the repeatability of the core design of the models.