NEWS: 22.04.2024

Plymouth Science Park gives hands-on experience of new Stratasys Polyjet and FDM machines

Plymouth Science Park is the largest centre for science and technology in its region, and it has just made a significant investment in two new...

NEWS: 10.04.2024

First installation of Stratasys F3300 FDM 3D printer from Laser Lines into UK

Laser Lines has sold the first two Stratasys F3300 Fused Deposition Modelling (FDM) 3D printers – the first installation in the UK– to BAE...

NEWS: 21.03.2024

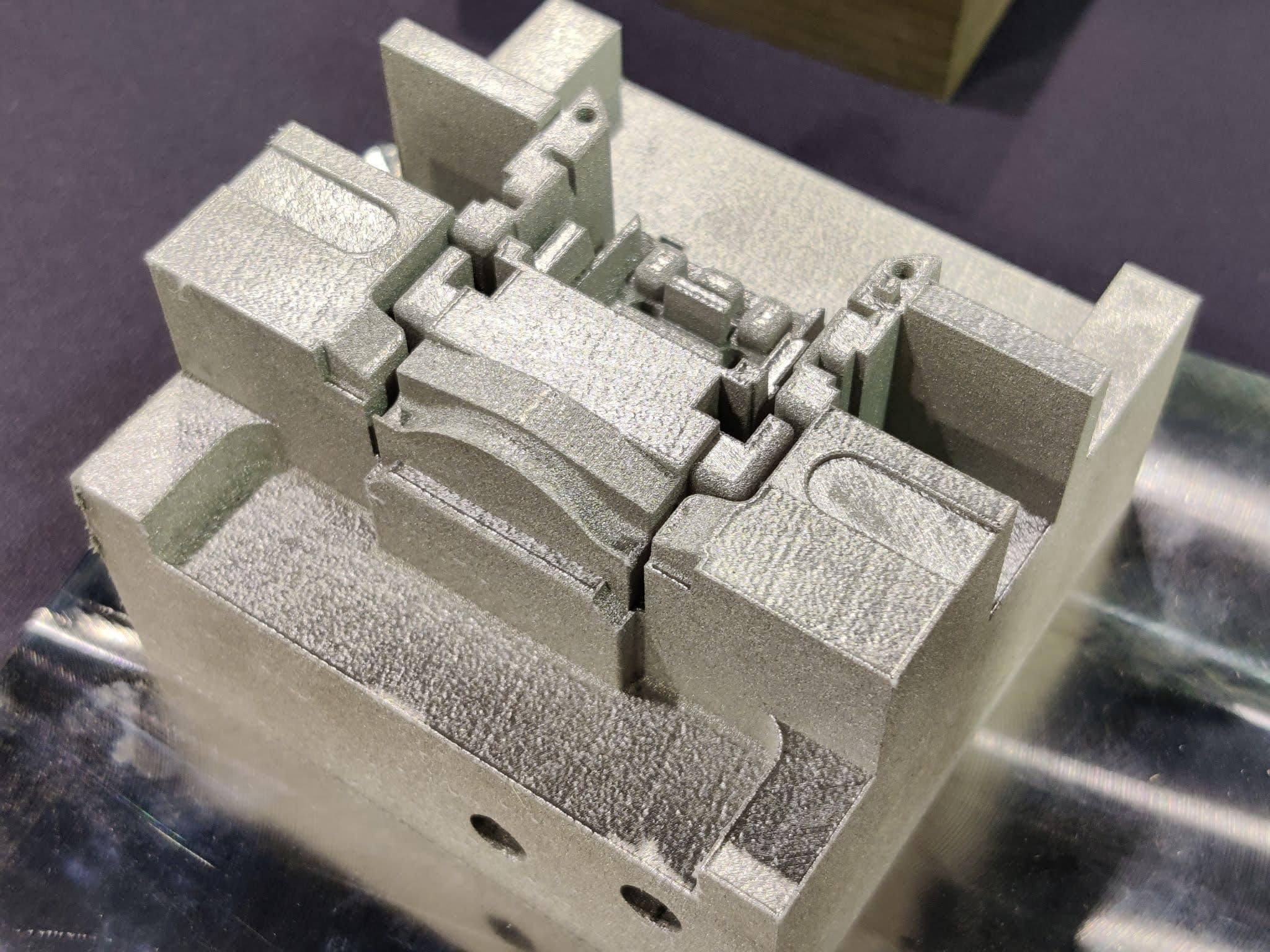

Xact Metal partners with Uddeholm to Offer Corrax Tool Steel Powder

With an aim to expand access to affordable metal 3D printing for small-to-medium size companies and decentralize additive...

NEWS: 05.03.2024

Reduced manufacturing costs with powerful 3D printing solutions from Laser Lines at MACH

This year’s MACH (NEC, 15th – 19th April) sees Laser Lines with two stands at the show demonstrating its cutting-edge laser...

NEWS: 20.02.2024

MMU Print City is UK first for Stratasys J850 with FabriX Innovation Kit from Laser Lines

Established over five years ago, Print City is an award-winning facility and the innovation hub for additive and digital manufacturing at Manchester...

NEWS: 05.02.2024

Additive Manufacturing and Industrial Laser Solutions on show with Laser Lines at Southern Manufacturing 2024

Laser Lines will be exhibiting a large range of laser marking and additive manufacturing technologies on stand E150 at Southern Manufacturing 2024,...

NEWS: 01.02.2024

The benefits and risks of switching to third-party materials

Mark Tyrtania, Sales Director at Laser Lines, writes about what to consider when thinking about using open materials. ‘Use any material...

NEWS: 17.01.2024

Meet Garth Stevenson, SAF specialist at Laser Lines

Real life experience and a renewed passion for creative thinking helps Garth explain opportunities and applications to customers – faster and...

NEWS: 09.01.2024

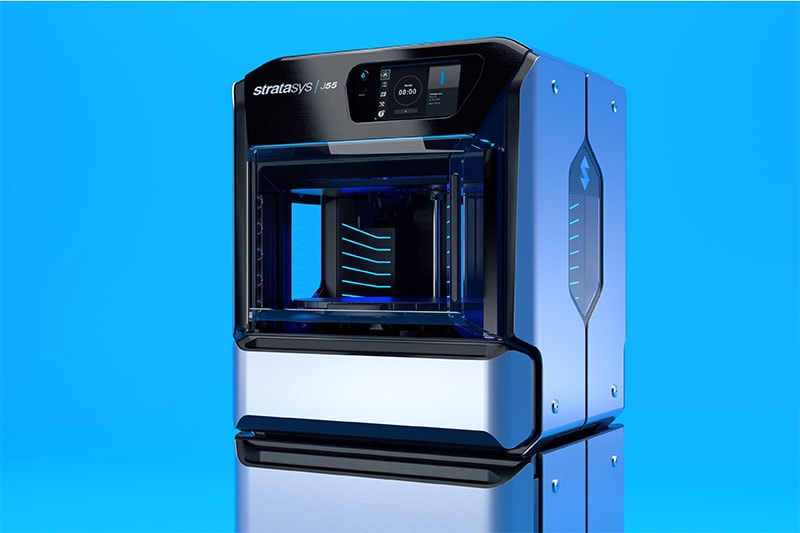

Which Stratasys Polyjet 3D printer is right for my business?

Polyjet 3D printers are helping businesses all across the world produce realistic parts that look and feel like the right thing, speeding up...

NEWS: 14.11.2023

Bolton University invests in second Xact Metal machine to expand capacity, improve teaching and help local businesses

What do you do after two years of success using the best value metal additive manufacturing machine in the business? If you are Bolton University,...

NEWS: 11.10.2023

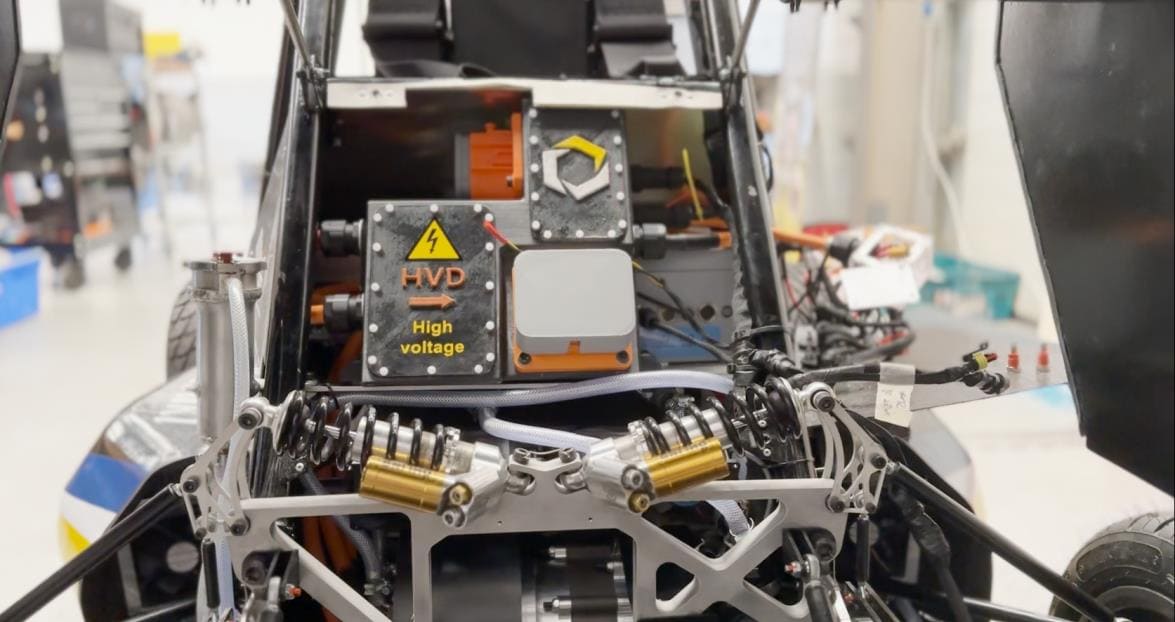

UGRacing (University of Glasgow) – Product Testimonial

Founded in 2005, UGRacing is made up of a team of highly motivated and talented students studying degrees ranging from engineering to law. The...

NEWS: 11.10.2023

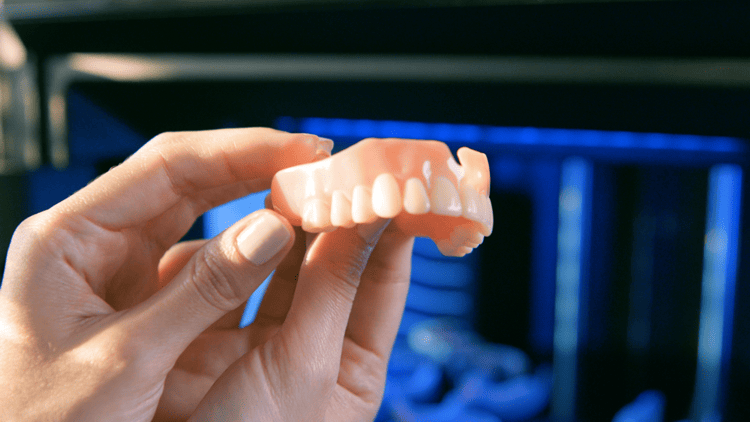

Discover the Future of Maxillofacial and Dental 3D Printing

Stratasys, renowned for its cutting-edge 3D printing solutions, and Xact Metal, a leader in metal 3D printing technology, offer game-changing dental...