Which Stratasys Polyjet 3D printer is right for my business?

Polyjet 3D printers are helping businesses all across the world produce realistic parts that look and feel like the right thing, speeding up design and prototype times and saving money. There are lots of different options available, so here, Phil Craxford, sales manager for Additive Manufacturing machines at Laser Lines, walks us through the range.

The first thing to say is that no one machine fits every need. I don’t think that there will ever be a machine that does everything. To work out which machine fits your needs the best, the easiest thing you can do is to speak to someone at Laser Lines.

Time and again we talk to customers who have preconceived ideas of what they need, but when we take the time to find out what they want to achieve in their business, they end up selecting a much better technology or machine.

That said, there are some general principles we can apply to the Polyjet range.

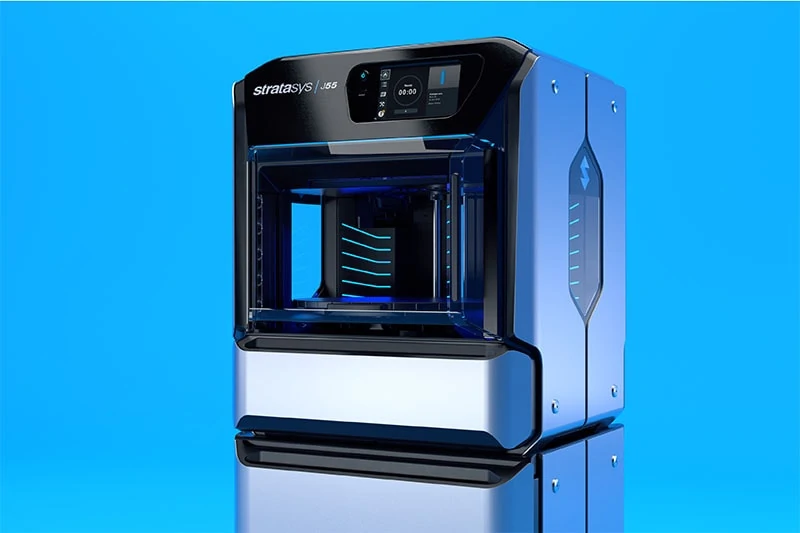

Stratasys J-series Polyjet 3D printers

The main function of the J-series is to produce full colour, validated parts for design verification, and sometimes end-use parts as well.

As technology has advanced, people expect to things that feel realistic. They are used to seeing nice renders on a screen, and now they want to see that reflected in a physical form. It helps speed up their design process. When you produce parts in the colour that they are destined to be at the end, you can quickly see if you need to make any changes before things go into full production.

J-series machines have the ability to mix materials, and some have the ability to produce full colour parts that are Pantone-validated. You can get realistic models straight from the machines, cutting down on finishing and painting.

The J-series is excellent for design houses, but it is also incredibly versatile. We have installed machines in aerospace, military and even medical environments printing medical-grade materials.

Which J series?

The quality of the part is the same across the whole series. The model you choose comes down to the size of the part, what you want to output and your budget.

The J55 Prime is targeted at smaller design houses. If you want to print in full colour, this is your starting point. The machine can fit through a door and sit next to your desk quite nicely. You don’t need a great big workshop to have one of these machines. In the long term, it will save a smaller design house a lot of money that it would typically spend on outsourcing.

If you want to make larger parts, or more, smaller parts in one build, this is where the big machines such as the J826 Prime and J850 Prime come in. We use our large, in-house machines to produce multiple parts over and over again for our 3D printing bureau customers.

If you want to produce a lot of parts, then the larger machines are more cost-effective. Even though they need a larger investment to begin with, you get a faster return because of their higher output.

For those that need functional, flexible, full-texture parts for concept or functional designs, the J35 Pro is ideal at a very reasonable cost. Up to three materials can be used to print at once, and the machine is both quiet and small enough to fit into an office.

For high-speed concept modelling, a special print mode is available that uses DraftGrey material to produce parts even faster, helping you to speed up design decisions.

One of the best ways to start narrowing down which J-series machine is right for you is to download GrabCAD Print for free. Before you have even bought a machine, you can see the templates for each Stratasys printer, load parts into it, get build times and see how easy they would be to print on different machines.

Many people ask us how long a particular part would take to build on a 3D printer. If you download the software and become familiar with it, you can see for yourself. It is like a try before you buy.

Medical Polyjet machines

The J850 Digital Anatomy is a specialised machine designed for surgical training. It uses specialised medical materials, such as TissueMatrix, GelMatrix and BoneMatrix. You can fully replicate body parts, such as a hand. The skin and bone look and feel accurate, with realistic bone density.

It saves a lot of time and money, so surgical trainers don’t need to use dead bodies or animals anymore, or the facilities and permits you need to work with cadavers.

In addition, on the medical side, there are dental machines such as the J3 DentaJet and J5 DentaJet, which use biocompatible materials for manufacturing items such as orthodontic devices. Just get in touch with us to find out more about how these can help your dental practice get ahead.

Call Phil and the Laser Lines team on 01295 672599, or email [email protected] to find out more about how the Stratasys Polyjet range of 3D printers can help you save time and money.