How Xact Metal re-wrote the metal 3D printing rulebook with its low-cost machines

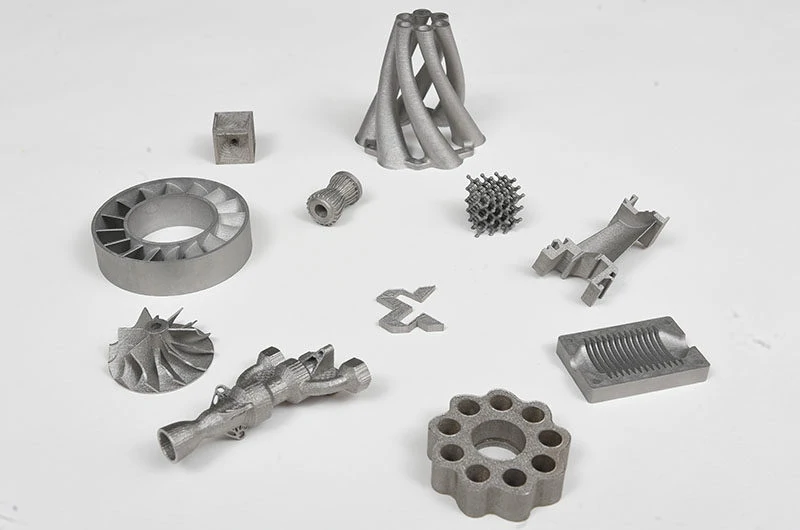

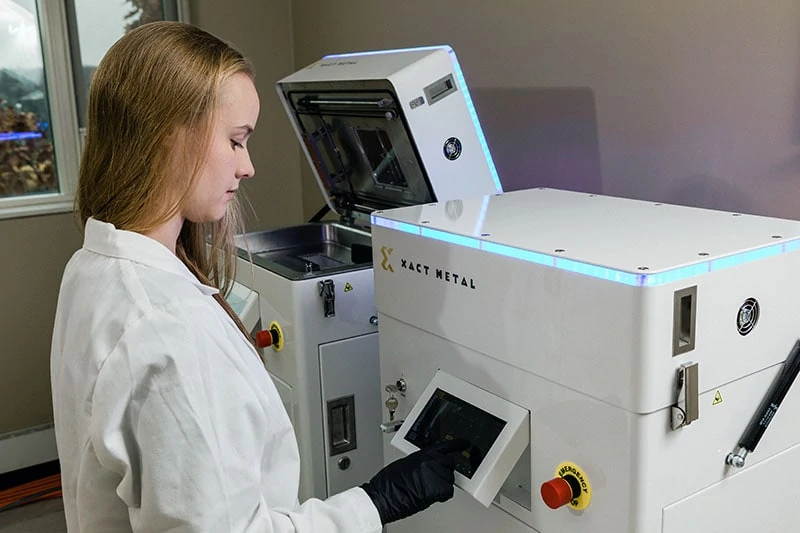

Xact Metal’s metal 3D printing machines are dramatically lowering the price for companies to receive the benefits of metal additive manufacturing. Its XM200C and XM200S machines are one of the best powder-bed machines available for the price right now, and Laser Lines is the only UK company to sell and support them.

We caught up with the company’s Chief Executive Officer, Juan Mario Gomez, to find out more.

“People are really connecting with our story and our mission,” Juan Mario continues. “We had people queuing up to take selfies next to our machines! Our customers are telling us that they have often wanted to get into metal 3D printing, but it has traditionally been out of reach for them. We make things more accessible, available and affordable. When customers start looking around and find us, they are really excited because they can get the solution they want, at a price they can afford.”

In the beginning

It all started a few years ago when the team initially had very different ideas. “We started trying to develop a multi-metal printing machine, so that you could put a strong metal next to a softer metal, which was very appealing to some of the research institutes we were talking to. During our R&D phase, we built a prototype with very little money and we realised that we could use our experience doing that to serve a much greater need.

“The number one problem in the industry was not the performance of the existing metal printers, it was the price. Everybody had been putting more lasers into their machines, but that had been only making the machines more expensive – millions of dollars in some cases. But if we could get the affordability of metal printers right, we could serve a large segment of the market whose needs had been unmet.

Switching from plastic printing

“Most people are still printing in plastics. It was so expensive to switch to metal before us – if you wanted to get into metal and you were a medium-sized company, you had to bet the whole company’s future on it. But we have now reduced the price of a machine to the point where our machine fits into a normal capital expenditure budget, so it is more a case of a company spending what they do every year on a new CNC machine or similar equipment.”

So, is this the end for the million-pound metal 3D printer? “Not yet,” says Juan Mario. “There is still a market for the expensive, large machines our competitors make. If you’re going to use one of these machines to build an automotive, aerospace or automotive component and produce it in large quantities, then the printer has to be super-high performing. But not everyone needs that printer.

Perfect for prototyping and tooling

What sort of customers are getting the benefits from the Xact Metal systems? “Small and mid-size companies are the obvious beneficiaries” says Juan Mario. “There is so much prototyping that needs to be done. Medical applications, aerospace applications, automotive applications and general engineering applications all benefit from our machines.

“There are also large time and money savings to be had in tooling. One of our customers in the automotive sector used our machine for its tooling to support its production, and it saw a return on their investment in just nine months.”

Bypass the central lab

But there is also another segment of the market that Juan Mario says is benefitting from Xact Metal’s knowhow. “At large companies that have invested in large, expensive metal 3D printers, the machines are often located in a central lab. That’s great if your desk is next to the central lab. But they are often busy. And if your office happens to be someplace else, you have to wait days or weeks to get your part.

“With the lower price offered by our machines, companies can distribute several machines throughout the organisation and put them where the work is happening. Designers and engineers can print overnight and come in the next day to find a brand-new part.

“Here’s another example. At Penn State University, historically they have had one metal 3D printing lab. That lab is full of work for the US Navy and other industry partners. If you are a professor or student, you can’t really go and use the printers because the lab capability is inaccessible to others. Since we got involved, they have one of our machines at the Learning Centre that the undergraduate students can use in their senior design class.”

Coming to the UK

How does Xact Metal plan to expand out of the US? Juan Mario’s team have been working hard to set up a reseller network in Europe over the past year. “It’s imperative that we are local. We need to be available to customers in Britain with a British company that understands the UK market. We need salespeople that are technical and entirely independent from us.

“Just as important to us is that we have exceptional support provided locally by people who know what they are doing, who are close to our customers and are available during UK hours.

“We couldn’t be luckier to have Laser Lines as a partner. Laser Lines is the one of the top resellers of 3D printers in the UK. Not only can it sell our machines to customers in the right way for the UK region, it can service the machines and respond to any support enquiries without waiting for the US office to wake up. Together with Laser Lines, we are ready to be in the UK. Our machines have all the necessary UK certifications, and we know our brand is in stronger with Laser Lines.”

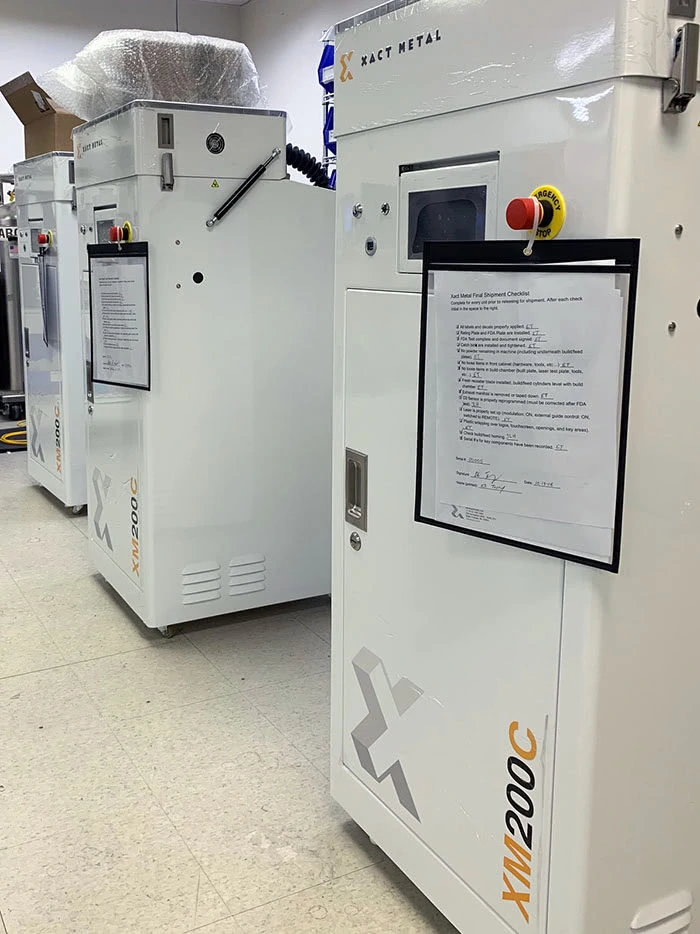

Fast delivery times

“We hear stories of orders being submitted for rival machines and them turning up many months or even years later. Who can get excited about that? We have worked hard to ensure that, when we get an order, the customer will have the machine within two months of that order.”

Focussing on quality

How is it possible to be that fast? “One of the ways we have done that is by building the machines ourselves and not contracting the build out to someone else. That makes us a lot faster than some of our competitors.

“It has also improved the quality of our machines. Our engineering team sits right next to the production line. If there is a problem, they can make a change straight away. If there is something that is not working in the field, the teams can talk, get a solution together very fast and get it fixed quickly.”

Looking to the future

It has clearly been a whirlwind few years for the company. What’s next? “We are in this for the long term. We are serving a global customer base in North America, Europe and Asia and in the next few years you will see us scale up.

“We have ambitions to launch a mid-sized printer that will be able to produce larger parts and print multiple parts at once using the architecture that we have developed. And just like our existing machines, it will be a low-cost machine.”

We look forward to the chance to continue to support the next generation of innovative manufacturing solutions, powered by metal 3D printing.

If you want to know how Xact Metal’s machines can help you make the switch to metal 3D printing, get in touch with us on 01295 672599 or email [email protected]. It may cost less than you think.