Improve your jigs and fixtures with GrabCAD Print Advanced FDM

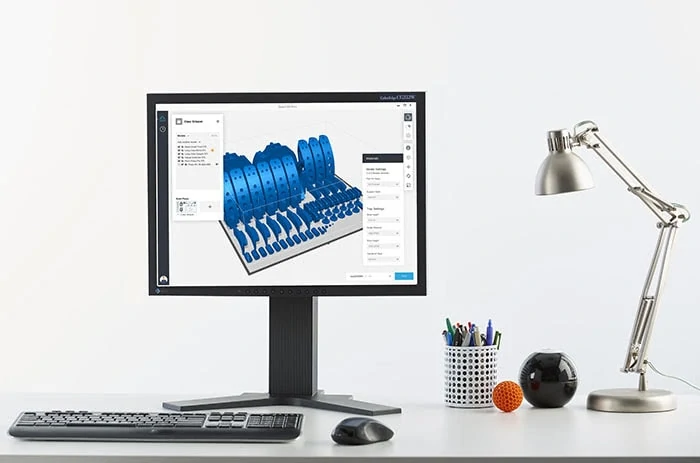

With GrabCAD Print Advanced FDM, the new cloud-enabled software from Stratasys, parts can be made easier and faster, taking advantage of the unique capabilities of the FDM process. But you would be forgiven if you didn’t know that.

As Phil Craxford, Sales Manager at Laser Lines, says: “3D printing enables you to think differently about product design. A lot of people want to continue working in the same way and then just save their work as an .STL file, but with this new software, the design and make process is easier and much faster.

“There are huge benefits to using this to make parts compared to traditional machinery methods, but it is one of the industry’s best kept secrets. We need to do a better job of explaining this improved functionality.”

Formerly known as GrabCAD Jig & Fixtures, the software is ideal for creating these parts. GrabCAD Print Advanced FDM provides a powerful, easy-to-use toolset that gives you the parts you need by controlling FDM build attributes through familiar CAD data.

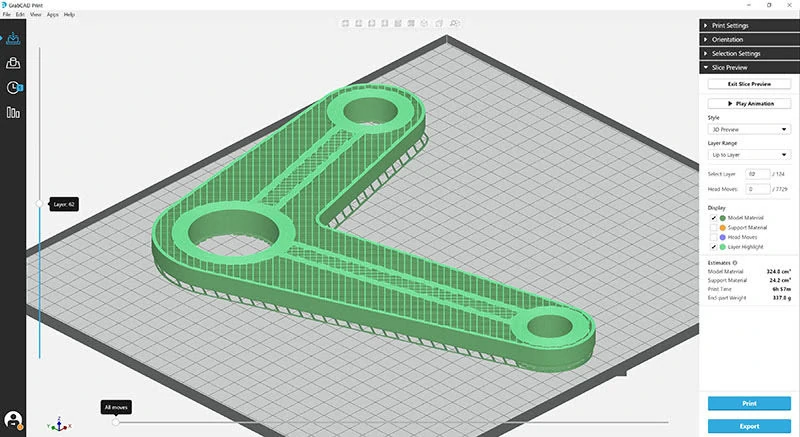

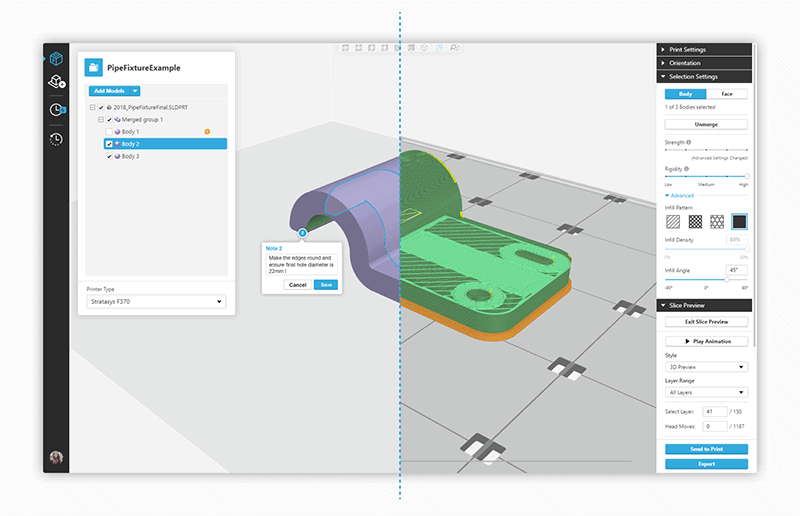

Working directly on your CAD models, you can specify areas of strength and rigidity, control infills, ensure sufficient material around holes with inserts, reduce the need for support in horizontal holes, and avoid seams. All necessary tool paths are then automatically calculated by the software without requiring manual manipulation of individual layers, which means less time in job preparation as well as improved part characteristics.

You can also use the software to determine the weight and usage of materials and see where you can make changes to save build time and material usage to cut costs.

Supported files and materials

The software can be used on and offline and uses raw CAD data rather than .STL files.

It supports the following printers:

- Stratasys F170

- Stratasys F270

- Stratasys F370

- Stratasys F900

- All Fortus systems (excluding the 250mc and 360mc)

It also works with a wide range of materials.

Adjustments

These are a whole range of fine adjustments that can be made to the faces and bodies of your 3D printed parts that are unique to the software. Some of these include the ability to change the density of the infill pattern, as well as the chance to choose a specific infill style, offering a way to strengthen parts where needed while keeping other areas lightweight. You can adjust the number of contours around vertical surfaces and solid layers around horizontal surfaces.

The tool helps you make your part self-supporting – should you have holes in your geometry that will print horizontally, you can change them to a diamond shape so that they don’t require support material. And there are plenty more adjustments that can be made using the easy-to-use interface.

Communication with manufacturing colleagues

Phil continues: “As someone who has previously worked in design and development, GrabCAD Advanced FDM is really impressive and it would have saved me loads of time in my previous role. If you would like to find out more about the software and its benefits, just get in contact and we will run you through it in more detail.”

Find out more about GrabCAD Print Advanced FDM by emailing the Laser Lines team on [email protected] or calling 01295 672599.