Why Polyjet is perfect for rapid prototyping

By Richard Hoy, Laser Lines’ in-house applications expert for 3D printing

Before Polyjet printing, the main way to prototype was with old-fashioned, hand fabrication, machining and assembly. Needless to say, it was a slow and expensive process, so it’s no surprise that we still see Polyjet as a dramatic breakthrough.

By replacing the time-consuming techniques of the past, Polyjet enables designers and engineers to quickly build, print, produce and create a scale model of their end product. And unlike the handmade mock-ups that went before them, these prototypes bear a striking resemblance to the final product. Indeed, Polyjet has brought us closer than ever before to an accurate representation an of original, 3D CAD design.

Why it’s so useful

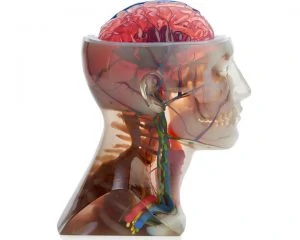

It is now possible for a surgeon to use an exact 3D-printed replica of a patient’s heart for medical analysis before operating. Similarly, dentists are making impressions of patients’ teeth to produce 3D-printed moulds that will inform detail surgery.

Polyjet printing also excels in its unrivalled range of materials. We can now create rigid or flexible parts, and even combine several materials in one model. A great practical example is the prototyping of toothbrushes and razors, which feature overmolding of several materials in one product.

The higher-end Polyjet machines offer an unprecedented range of colours too. The Stratasys J750, for example, is the world’s first printer with the ability to produce objects in any of 360,000 continuous colour tones. That’s quite a selection.

Future of Polyjet

Looking to the future, I am predicting giant strides forward for Polyjet printing. The speed of process is likely to improve. We will see the range of materials expanding too, which will give prototypes greater strength and durability. But of all the inevitable advances, increased accessibility will have the biggest impact.

While we are not likely to see high-end Polyjet printers for sale in supermarkets any time soon, growth in the number of on-demand services offered by bureaus such as Laser Lines’ will make Polyjet printing an affordable option not just to big brands buying their own machines, but to SMEs too. Then the possibilities can only increase.

To talk to us about how Polyjet printing can modernise your prototyping process, email us at [email protected] or call 01295 672599