Validated materials are produced both by Stratasys and third parties and have undergone basic testing for quality, reliability and repeatability. This removes a lot of the risk involved in adopting a new material, while allowing you to bring the latest production techniques to your business as quickly as possible.

Here are the details of the materials in the validated programme:

Standard plastics

FDM HIPS

FDM High-Impact Polystyrene (HIPS) combines many of the best properties of ABS with a higher impact resistance for extra durability.

Its low cost makes it perfect for prototyping, enabling you to produce several iterations quickly to help narrow down your design options. It is also useful for jigs, fixtures and assembly aids and can easily be recycled. Download specifications.

Engineering plastics

Kimya PC-FR

This material is highly flame retardant and conforms to both the EN45545-2 and R1-HL2 fire safety standards. With the same, and in some instances better, mechanical strength than standard Stratasys PC material, it enables you to manufacture parts faster and cheaper than when using traditional injection moulding.

It is compatible with Stratasys SR-100 soluble support. Download specifications.

Kimya Kepstan PEKK-SC

Parts that need to be resistant to high temperatures, abrasion and chemicals are a good fit for Kimya Kepstan PEKK-SC. These are useful qualities in many industries, but one is in oil and gas, where its ability to withstand exposure to fuel and lubricants is perfect for parts such as a backup ring, where traditional manufacture wastes 60% of material. Additive manufacturing removes the wastage and reduces part production time.

It is compatible with Stratasys SUP8000B breakaway support.

Contact us at Laser Lines for more details and to request a spec sheet.

Covestro Addigy PA6/66-GF20 FR LS

With 20% glass filled nylon, PA6/66 has high levels of stiffness and strength, while complying with fire, smoke and toxicity regulations such as EN45545-2, NFPA 130 and SMP 800 C. It uses a non-toxic flame retardant, and its glass-filled composition provides good thermal performance at higher temperatures.

Compatible with SUP4000B breakaway support, it can be used to create many different parts where extra strength is called for. This includes many railway applications, where it is perfect for parts such as arm rests, coat hooks and electrical covers, where the cost of replacing obsolete parts using traditional moulding and machining is very high. Download specifications.

PC-ABS in red

Ideal for functional prototyping, PC-ABS mixes the best properties of ABS and polycarbonate for a high impact strength.

It is available in black as a Stratasys preferred material, but if you would like it in red, it is part of the validated material selection. Download specifications.

Polycarbonate (PC) in red and black

This strong, heat-resistant material is available in black and red as part of the validated materials programme, in addition to the white colour in the standard preferred material selection. Download specifications.

High performance

ULTEM™ 9085 resin in red, grey and white

A versatile, self-extinguishing material that is highly effective in aerospace applications, ULTEM™ 9085 resin is now available in more colours as part of the validated materials programme.

You now have the option of red, dream grey, white, jana white, gunship grey or aircraft grey as validated materials, in addition to the standard black and tan colours that make up the preferred materials range. Download specifications.

VICTREX AM 200

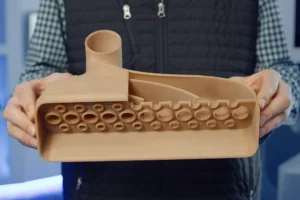

Intended for use in aerospace applications, Victrex AM 200 is for high demand applications that require chemical resistance, strength and thermal stability. It offers performance like that achieved when using PEEK materials, but without the typical challenges associated with those.

It has been designed by Victrek specifically for FDM 3D printing and is manufactured using its LMPAEK polymer technology. AM200 supports reduced processing temperatures and greater control over crystallinity rates for stronger, more isotropic parts than PEEK alternatives.

It pairs with SR-100 soluble support and is ideal for parts such as brackets and manifolds. Download specifications.

Validated vs preferred materials

The main differences between validated materials and Stratasys preferred materials, as its existing in-house range is known, are:

- The formulation of validated materials may change without prior notification.

- Print parameters are only improved at Stratasys’ discretion, rather than continuously.

- There is no guarantee of supply chain continuity.

- There is no production lot validation of polymer attributes, such as flammability.

Currently, you need a Fortus 450mc machine to use Stratasys validated materials and older models may need an all-material license and an upgrade to a hardened system. Get in touch with us to find out what is needed in your case.