DLP 3D printers: Stratasys Origin One

Find out more about DLP 3D printers

Stratasys Origin One

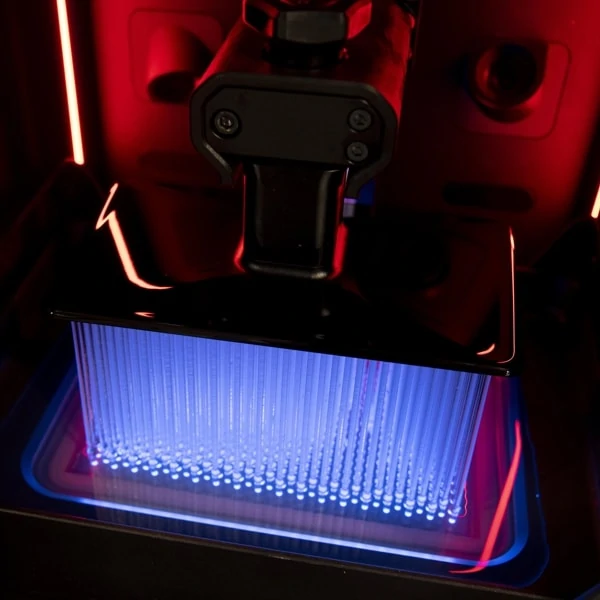

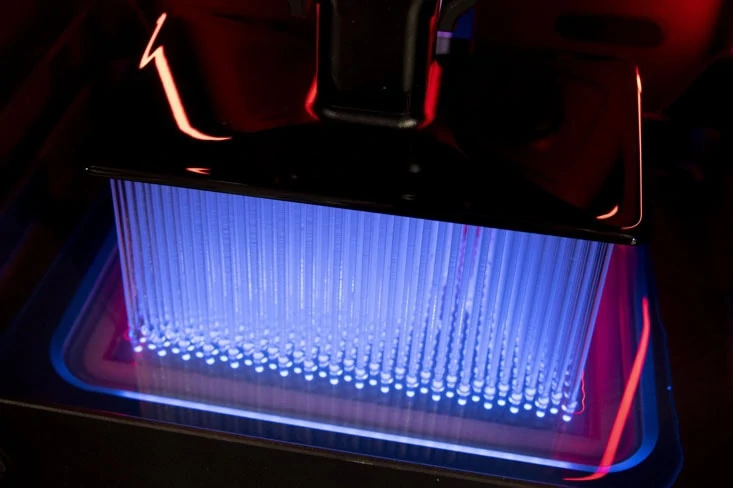

Origin One is an evolution of Digital Light Processing (DLP) and vat-photopolymerization, based on new Programmable Photopolymerization (P3) technology where light is selectively curing liquid resin. Expand your production with a fast and highly flexible capability with unmatched part to part consistency.

Low force pneumatic separation enables Origin One’s Programmable Photopolymerization (P3) process to print complex geometries, including fine features and large cross-sections, without the need for supports. The P3 process offers exceptional surface finish, equal to CNC machining and injection moulding, and users can manufacture on demand without inventory or retooling penalties.

Key Features

- On-board analytics, combined with automatic pressure, separation force and temperature regulation, ensure the first part is the same as the last.

- Temperature controlled process, adjusted on build chamber and resin interface

- Best-in-class surface quality, mechanical properties, accuracy, and repeatability.

- Can replace injection moulding in many applications.

- Low separation forces

- True Isotropic Properties & Best-In-Class Accuracy

- System has been verified for fastest DLP time-to-part print times

- Wide range of single component, commercial-grade materials, developed on and validated for Origin One including rigid, elastomers and high temp resins

- Change materials in minutes

- High accuracy materials enable print details of less than 50 micron

- Smooth, beautiful surface quality without secondary finishing, sanding, painting or additional processing

- Exceptional injection moulded part quality, whether it is a one-off or one of hundred’s

A manufacturing grade 3D printer

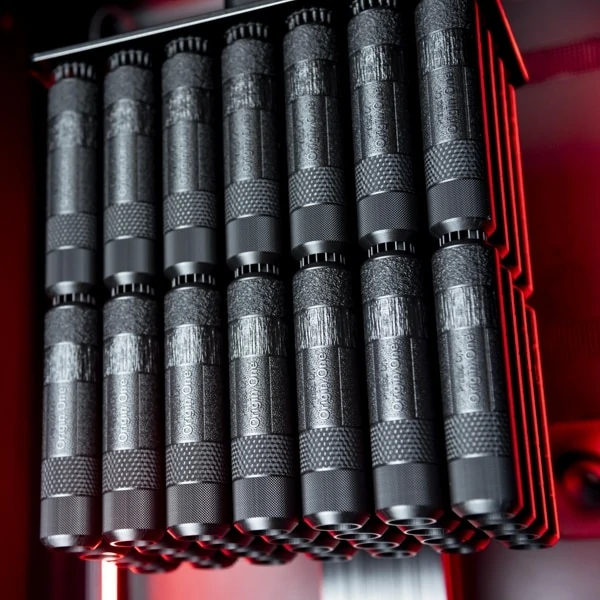

The Stratasys Origin One puts mass production of end-use parts at your finger-tips. With an optimized build volume, its compact footprint and minimal power requirements enable manufacturers to efficiently maximize production capacity per sq ft. The result is a simple and fast post-processing workflow, offering minimal facility requirements and making scaled production feasible. High throughput, combined with best-in-class repeatability, will see you expand production without delays, so you can launch faster and respond flexibly to shifts in demand, while maintaining minimal inventory.

Comprehensive range of materials

The Origin One offers comprehensive material options. These include heat-resistant materials which are available for application-specific requirements involving flame smoke and toxicity, HDT or moulds. There are impact-resistant resins for functional applications that need to perform under stress and high-load conditions, and medically certified materials which are ideal for devices where aesthetics, durability and biocompatibility are critical. Resilient, high-resolution elastomers offer excellent tear strength or rebound performance, and there are the standard fast-printing materials which are ideal for end-use applications requiring cosmetic surfaces, fine features and high accuracy.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

192 x 108 x 370 mm (7,672 cm3)

-

SYSTEM SIZE

49 x 51 x 113 cm

-

TECHNOLOGY

Programmable PhotoPolymerization P3

-

MINIMUM FEATURE SIZE

Material and design dependent, as low as 50μm

-

RESOLUTION

4K light engine

-

PROCESS ENERGY

UV (385nm) and thermal

-

SOFTWARE

Origin One cloud based web application

CASE STUDY: MEDICAL

Ramping up to half a million 3D printed test swabs

When the COVID-19 pandemic hit, so did an urgent need for large supplies of personal protective equipment (PPE). Origin One 3D printers provided a solution.