Stratasys’ Origin One and Origin One Dental printers are optimised for the on-site manufacture of precision parts, quickly and at a low cost. Using Programmable PhotoPolymerization (P3) technology, these transformative devices give access to new, innovative materials, with diverse strength, flexibility, heat resistance, and biocompatible properties.

Resins have long shelf lives and can be delivered in batches up to 10kg. When paired with Origin One and Origin One Dental machines, they enable the manufacture of precision mechanical, medical or end use parts, each with a high-quality finish, and details as small as 50 microns.

Laser Lines’ engineers are on hand to discuss the machines in more detail and can help select the most appropriate material or combination for any job. Below is a short guide to some of the material options on offer.

KeyGuide by KeyPrint

Strong without being brittle, and easy to polish, KeyGuide is autoclave and colour stable and delivered in 1kg batches.

KeySplint Soft by KeyPrint

Strong, yet flexible, it is ideal for the manufacture of patient-specific night guards, bleaching trays, and dental splints. While its flexibility ensures that patients wearing parts manufactured using KeySplint Soft remain comfortable, it is simultaneously tough enough to protect teeth from grinding and similar disorders.

Loctite 3D 3172 High Impact by Henkel

Finished parts can be polished, making it suitable for use in the development of both consumer parts and in manufacturing aids, brackets, and jigs. Both durable and very strong, Loctite 3D 3172 has an elongation at break of more than 100%, good machinability and a good surface finish.

Loctite 3D 3843 High Toughness by Henkel

It has a relatively high degree of elongation at break, and excellent flexural and tensile physical properties.

Loctite 3D 3955 by Henkel

Designed with a Heat Distortion Temperature (HDT) of 285°C, this high-performance material is flame retardant, making it suitable for use in heating, cooling, and ducting applications, thanks to its ability to avoid deformation in extreme environments. It is the first 3D photopolymer to comply with both vertical burn and aerospace FST standards.

Available in black and printable at 65°C, Loctite 3D 3955 has the highest tensile modulus of any material in its category, and elongation of just 2.1% at break.

Loctite 3D IND402 Rebound by Henkel

Ideal for use in producing lattice-like structures, this material demonstrates good rebound performance and true elastomeric behaviour with 230% elongation at break – the highest rating for any material in its class. Available in black, it has a Shore A hardness of 75, has good tear strength, and is exceptionally durable when subjected to compression forces.

Loctite 3D IND403 High Modulus by Henkel

Loctite 3D IND403 is an excellent choice for parts that require a high-quality finish and predictable dimensional accuracy, such as moulds, or interior applications within the automotive industry.

Loctite 3D IND405 Clear

It is ideal for use in the production of guides and microfluidic devices for the precise control of fluids on a sub-millimetre scale. Moderately flexible, it has excellent strength and impact resistance and is ISO 10933 -5/-23 biocompatible compliant.

Loctite 3D Med 412 by Henkel

Moderately flexible and with excellent strength, this medical grade material is ISO 10993-5 and ISO 10993-10 certified. Tough, yet with superb elongation, it achieves 110% elongation at break, has ultimate tensile strength of 37 MPa, and a Shore D hardness of 78.

A transparent material, Loctite 3D Med 412 is a suitable replacement for medical-grade polypropylene in the manufacture of lab equipment and single-use medical instruments.

Loctite 3D Med 413 by Henkel

Facilitating excellent print accuracy, this is a high precision, engineering grade material with an outstanding surface finish, and excellent flexural and tensile properties for production of functional parts.

Origin DM100 by BASF

Origin DM200 by Stratasys

As a low viscosity option, DM200 can flow more quickly through the printer to reduce job times by as much as 33%, making this off-white material the ideal medium for use in high-volume dental labs.

Origin OML Exploratory Materials

Access to a wide range of unsupported exploratory materials allows Origin One printer users who want to experiment with innovative manufacturing techniques to produce a wider range of parts than would otherwise be possible.

Offering early access to novel materials, the exploratory materials range is suitable for use in such diverse manufacturing jobs as the production of electrical and ceramic parts.

P3 Deflect 120

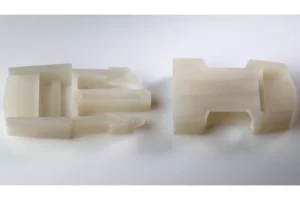

A heat-resistant material with good strength, this material is useful when a good elongation at break is required. With a low viscosity and high green strength, parts that have challenging geometries are its forte. Examples include connectors, wiring housings and mould tools. Manufactured by Evonik, this durable and tough material is estimated to improve part strength by 10% compared to that seen on comparable, rival systems. With good weatherability, it is available in black.

P3 Stretch IND 475

This true elastomeric material has been designed to give a good balance between strength, elongation and hardness. Available in black, it is useful when employing lattice structures or for functional prototyping. It has good resilience, tear resistance and the ability to rebound quickly back to its original shape after a load has been applied. This makes it useful for parts such as flexible seals, cushioning pads and dust gaskets. It is printable at room temperature and produces fast results with minimal shrinkage. This material only requires ultraviolet postcuring and should be post-cured while submerged in water. Download data sheet.

Somos QuickGen 500 by Covestro

Being almost entirely clear at the point of production, Somos QuickGen 500 is ideal for use in the manufacture of detailed and semi-flexible parts for applications including fluid analysis.

Stratasys Dura56 by Loctite

Ultracur3D ST45 by BASF

Combining strength, impact resistance and toughness, this general-purpose material has low viscosity for high-speed printing and a reduction in post-processing times. Optimised for use in functional parts demanding both accuracy and mechanical strength, Ultracur3D ST45 is available in black and clear, and is certified ISO 10993 biocompatible. Finished parts exhibit good surface finish and meet UL-94 standards for plastics flammability.

To find out more about Stratasys Origin One machines, how they can contribute to your manufacturing workflow, and the most suitable material for any job, contact Laser Lines today. Call 01295 672599 or email [email protected].