Flexible yet repeatable

Whether manufacturing prototypes, production parts or jigs and fixtures, the F123 series is designed to be simple to use, with automatic calibration and straightforward material swaps. Machines in this series can be used in an office by your staff with no special facilities or air filtration required. For demanding applications, the Stratasys F190CR and F370CR machines can even print with carbon fibre filled material for stronger and lighter parts. In a recent study, the F123 series produced reliable results 100% of the time, compared to 79% for its closest competitor, while also being 45% faster than the competitors it was tested against.

Plenty of materials

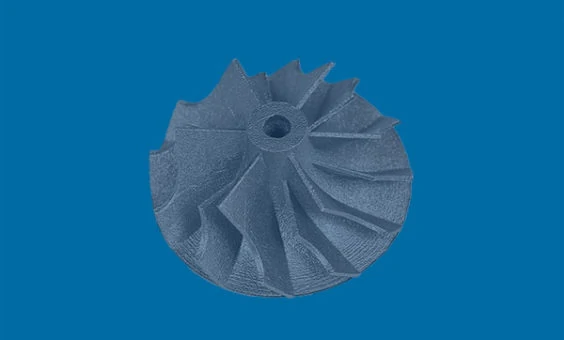

F123 series printers support a range of materials, including carbon fibre filled Nylon and ABS, PC ABS, ASA, Elastomers and many other engineering-grade materials. With fast and easy material swaps, auto-calibration, and an enclosed, insulated build chamber, the F123 series provides accurate, repeatable 3D printing suitable for the office, classroom, or factory floor.

Stratasys F123 benefits

- Industrial-grade capability, while being simple to use

- Fast and easy material swaps keep your production process running longer

- Carbon fibre additive manufacturing available with certain models

- Machines calibrate automatically to ensure repeatable results

- Up to four material bays

- An easy-to-remove, soluble support material is available

- Large build size options, up to 355 x 254 x 355 mm

- The enclosed, insulated build chamber has an auto-locking door

- Noise measures at a maximum of just 46 decibels during the build

CASE STUDY: LOW VOLUME PRODUCTION

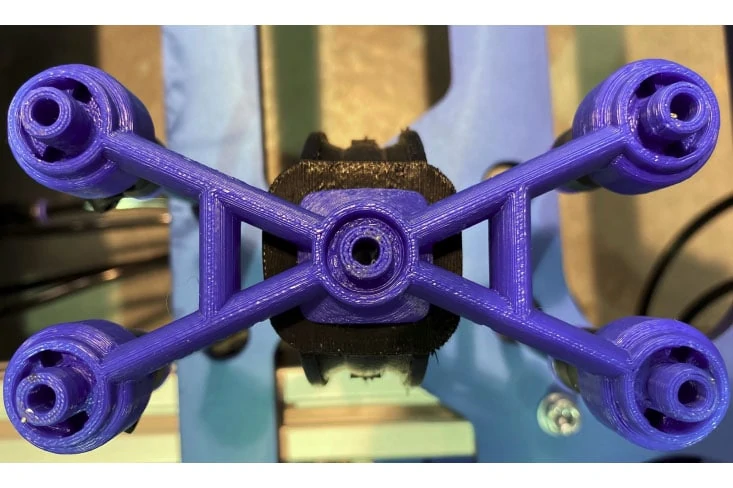

Form Automation

This robotics company relies on the Stratasys F370 3D printer to quickly and cost-effectively produce replacement end-of-arm tools for its network of robots.

With the F370, I can now have a new tool within just a few hours. The cost to produce 3D printed end-of-arm tools is less than that of producing the same parts in aluminium.

Martin Grisdale, Company Director, Form Automation Ltd