Why Engineers Should Trade-In Their Objet3D Printers for the New Generation of PolyJet Technology

In the fast-paced world of engineering, staying ahead of technological advancements is paramount for success. One such groundbreaking innovation that has transformed prototyping and manufacturing is 3D printing. Among the numerous 3D printing technologies available, PolyJet has emerged as a game-changer, offering engineers a competitive edge in their projects. In this blog post, we will delve into the reasons why engineers should consider trading in their old 3D printers for the new generation of PolyJet technology.

Expand your applications

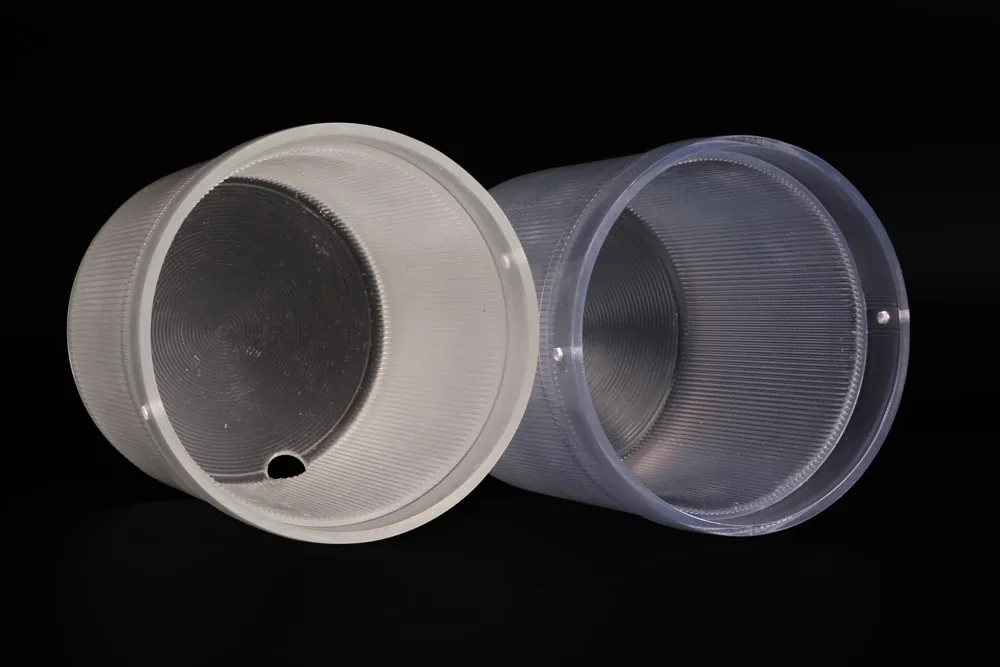

The J35 Pro allows for simultaneous modeling of three different materials, offering a wider range of applications. This printer enables gray scale shades combining both translucent and opaque materials. It also allows for the combination of rigid and rubber-like textures and mixed material parts. This process requires no resin replacement, thereby avoiding wasted material while saving on time.

End-to-end solution

Ease of use

New design features on the J35 Pro have significantly reduced the time required for user maintainability time by up to 50%. This improvement enables users to move directly from CAD to Print. The J35 Pro also introduces a revolutionary new water-soluble support material called WSS™150. This support material dissolves completely in regular tap water, eliminating the need for additional chemicals or complex processes to remove supports. This feature is particularly valuable when manual support removal might lead to parts breakage or damage.

Complete fit for the office environment

Odor free, and quiet at less than 53db, the J35 also has a smaller footprint. Boasting an almost 30% build tray-to-printer footprint ratio compared to 11% for Desktop printers, and a much smaller 4-6% ratio on your Eden/Connex 260 legacy systems, the J35 makes more efficient use of an office setting.

Improved productivity and throughput

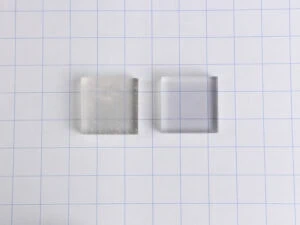

The PolyJet™ technology utilized by the J35 Pro is known for its ability to produce parts with excellent detail and smooth surface finish. This technology works by jetting ultra-thin layers of liquid photopolymer onto the build tray and curing them with UV light. This process allows for intricate designs and fine details that are difficult to achieve with other 3D printing technologies. The J35 Pro offers an increased build size – nearly double that of most desktop printers – and a 70% higher output when using the HQ printing mode.

Sustainability

The J35 Pro 3D printer offers an ideal solution for the current challenges faced by supply chains, providing several benefits that can transform the way businesses operate. By upgrading to the J35 Pro, companies can harness the power of on-demand and in-house printing. The use of the new water-soluble support material in conjunction with the J35 Pro further enhances the efficiency of the printing process. This support material dissolves entirely in tap water, eliminating the need for additional chemicals and making support removal a hands-free process. This simplifies post-processing and reduces the labor and time required to clean printed parts. Furthermore, the compatibility of the water-soluble support material with Stratasys L2S™ powder allows for safe wastewater disposal in accordance with local regulations. This eco-friendly approach ensures responsible and sustainable manufacturing practices, reducing the environmental impact of the printing process.

Improved cost per part

The availability of Draft Grey as a low-cost printing option provides a significant advantage for fast iterations during the concept stage of product development. With a cost that is approximately 50% cheaper than other materials, it allows designers and engineers to quickly iterate and test different design concepts without incurring high expenses. Also suitable for the J35 Pro are Functional advanced materials such as VeroUltra™ClearS, VeroUltra™WhiteS, VeroUltra™BlackS, Elastico™and Digital ABS Plus.

PolyJet technology offers numerous advantages over other 3D printing methods, making it an appealing choice for engineers and businesses seeking cutting-edge capabilities and superior results. The flexibility in material choices is another significant benefit of PolyJet technology. With a wide range of materials available, including rigid, flexible, transparent, and functional materials, engineers have the freedom to select the most suitable materials for each specific application. This versatility allows for the production of prototypes and end-use parts with diverse mechanical properties and aesthetics. Upgrading from older 3D printers to the new generation of PolyJet technology equips engineers and businesses with the latest advancements in 3D printing capabilities. Staying ahead of the curve with cutting-edge technology is crucial for staying competitive in an ever-changing industry and driving innovation in product development.

In conclusion, PolyJet technology presents a compelling case for being the go-to choice of 3D printing technology for engineers who seek high-quality printing, material flexibility, faster production, and reliable long-term support. Upgrading to PolyJet technology enables businesses to meet the demands of the industry and stay at the forefront of technological advancements.

Download the PDF: Stratasys J35 Pro Compared with other Desktop Machines