Stratasys helps Boeing and Ford see 3D printing from a new angle

Size has long been a limiting factor in 3D printing – but not for much longer.

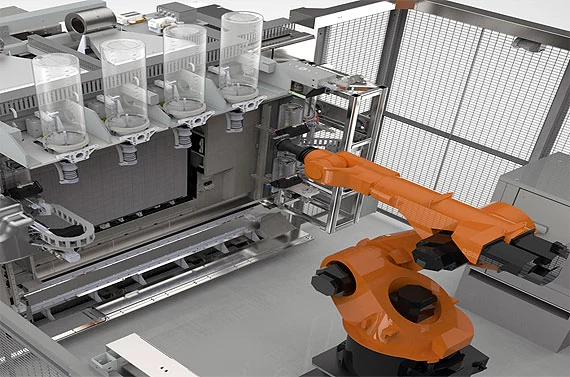

Stratasys has announced its Infinite-Build 3D Demonstrator, which flips the FDM process on its side and builds on end, rather than up from a bed. The technology, which mounts the deposition head on an eight-axis industrial robot, has already caught the eye of Boeing and Ford, and it isn’t hard to see why.

Where maximum print sizes were previously constrained by the internal volume of the printer itself, the lack of any build envelope constraints on an Infinite-Build device means the sky is the limit. Quite literally.

“Stratasys has really addressed its customers’ needs with the Infinite-Build 3D Demonstrator,” says Laser Lines Sales Director Mark Tyrtania. “The fact that it has gone into collaboration with experts in robotics and control, and Siemens on the software side, shows how serious it is about breaking new ground.”

Boeing is already using a prototype Infinite-Build device in its production centres, where the option to use multiple materials and print from previously inaccessible angles means it is capable of producing more complex, lightweight aircraft components. The Boeing device is the first instance we’ve seen of a 3D printer manufacturer designing bespoke hardware for its clients.

Customers decide

“Stratasys is very much building on its strategic partnerships here, and being consultative in its approach to customers,” says Tyrtania. “Rather than producing a product and then moulding the customer’s needs to suit, it is examining its customer needs first and making products to match. It is letting its customers define the market.”

Boeing isn’t the only company that sees the potential of this new approach to 3D printing. Auto-giant Ford is examining how it could further accelerate its already rapid production of completed vehicles by achieving its goal of printing automotive-grade parts at high speed, on-site.

Although still at the development stage, Tyrtania expects Infinite-Build to be ready for roll-out in the next couple of years. When it is, Laser Lines will be the first port of call for any UK companies looking to take advantage of the new technology.

Platinum Partner

As a Stratasys Platinum Partner and the largest reseller of Stratasys machines in the UK, Laser Lines was the first company in Britain to both demonstrate and sell the revolutionary J750, which as well as being faster than its rivals, is the only device currently capable of printing in over 360,000 distinct tones.

“Infinite Build will never be a mainstream product,” Tyrtania says, “as it’s getting into the realms of custom build, but if a company is big enough, has the resources and a long-term vision, the gates are open for collaboration on any level.”

In the meantime, Laser Lines’ high-end Production Series printers already cater for print sizes up to 1m across. The Objet1000 Plus industrial scale multi-material device is the ideal solution for rapid on-site parts production, while the Fortus 900mc, the most powerful FDM printer available, offers true lights-out operation, with up to two weeks of unattended build time thanks to its dual material bays and high-capacity material options.

Laser Lines’ on-site bureau also has a wide range of Stratasys machines on site for deployment as part of your production process, or on which to trial new processes.

You don’t need to work in the automotive or aviation industries for 3D printing to transform your organisation. Call us today on 01295 672588, or email [email protected] to find out how on-site production can revolutionise your product development.