When making production parts where increased rigidity and strength are important, SAF PA12 powder is the answer. Designed for high accuracy, Polyamide 12 (PA12) is stiffer than high yield PA11. Also known as Nylon 12, its properties make it excellent for parts such as brackets, housings, electric enclosures and industrial machine components.

We recommend using this powder for higher tolerance parts with complex geometries where dimensional accuracy is critical. If you are unsure whether SAF PA12 or high yield PA11 is best for your needs, please get in touch with us for a personalised recommendation.

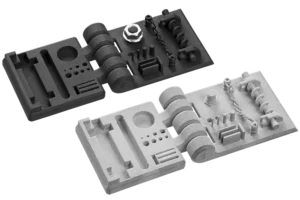

The Stratasys H350 machine that turns this powder into parts uses a technique called Selective Absorption Fusion (SAF). It provides excellent thermal control, producing production-quality parts with incredible consistency. The system provides best-in-class dimensional accuracy, while allowing for a very low cost per part. One of the ways this is achieved is via its high nesting density, meaning that that many parts can be produced in a single build.

As with other Stratasys SAF materials, only one fluid is required during the process. This is known as High Absorbing Fluid (HAF), and it is jetted onto a layer of the powder, which is then fused together by an infra-red lamp. Another layer of powder is then added, and the process repeats until the build is complete.

No support structure is required, speeding up the process and making it ideal for production applications. Plus, any leftover powder at the end of the build can be reused.