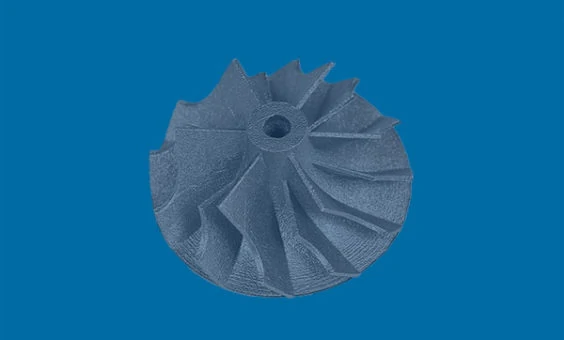

Origin One DLP machines are transformative 3D printers enabling mass production of end-use parts using a diverse range of high-performance materials. You can achieve industry-leading accuracy, consistency, detail and throughput with the P3 Programmable Photopolymerization technology.

Genera thinks about the entire additive manufacturing process, with its DLP printing and post-production machines optimised to increase repeatability, without creating unwanted mess.

We believe our P3 enabled Origin One 3D printers are ideal for addressing a wide range of in-demand production applications on a global scale

Chris Prucha, Stratasys VP of P3 Research & Development / Co-founder of Origin