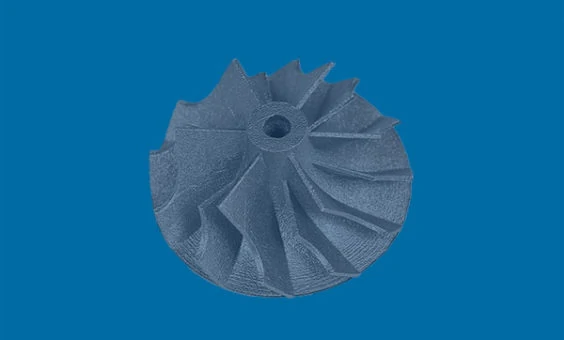

Metal 3D printing highlights

At Laser Lines we offer Selective Laser Melting to print components in metal. This is capable of producing near net shape parts.

Selective laser melting, also known as Metal Powder-Bed Fusion, is the process of melting and fusing metallic powder layer by layer on the printer bed, in order to form parts. After each layer is fused, the part is moved down so that the next one can be created. Parts created in this way have nearly 100% density.

The process begins with the creation of a 3D CAD model. The system software then slices the CAD model into a number of layers.

There are a wide range of metal materials available, including Aluminium, Cobalt, Copper, Iron, Nickel and Titanium.

The benefits of metal 3D printing

- The ability to build, light weight structures with the use of a lattice design.

- The capability of producing complex parts in one process thus reducing the need for assembly operations like welding or brazing.

- Ability to customise and create unique, individual products.

- The potential to create end use parts thus reducing time from concept to market

- Only use the material you require, reducing material cost and part weight. unlike traditional manufacturing excess material is recycled for use during the next build.

We make it easy for companies to get significant speed and cost savings when they invest in metal 3D printing.

Paul Tickle, Product Specialist, Laser Lines