CASE STUDY: AEROSPACE

GKN Aerospace enhances tooling capabilities

“The F900 3D Printer offers us the enhanced geometric freedom to create previously unthought of 3D printed tools, which then enable us to manufacture extremely complex parts that would be uneconomical or just physically impossible to create by any other...

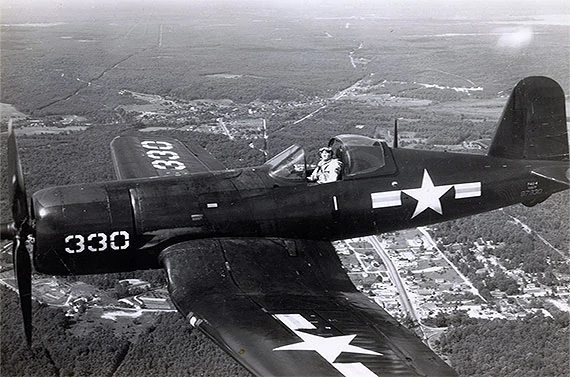

FDM Bureau Builds 3D Printed Parts for Recreational Aviation

Recreational aeroplane manufacturer ICON is working on their products becoming as popular as motorcycles & powerboats. ICON have used a FDM service bureau to not only save time & money but design end use parts for their latest A5 aircraft taking...