SLA 3D Printers: Stratasys Neo800

Find out more about SLA 3D Printers

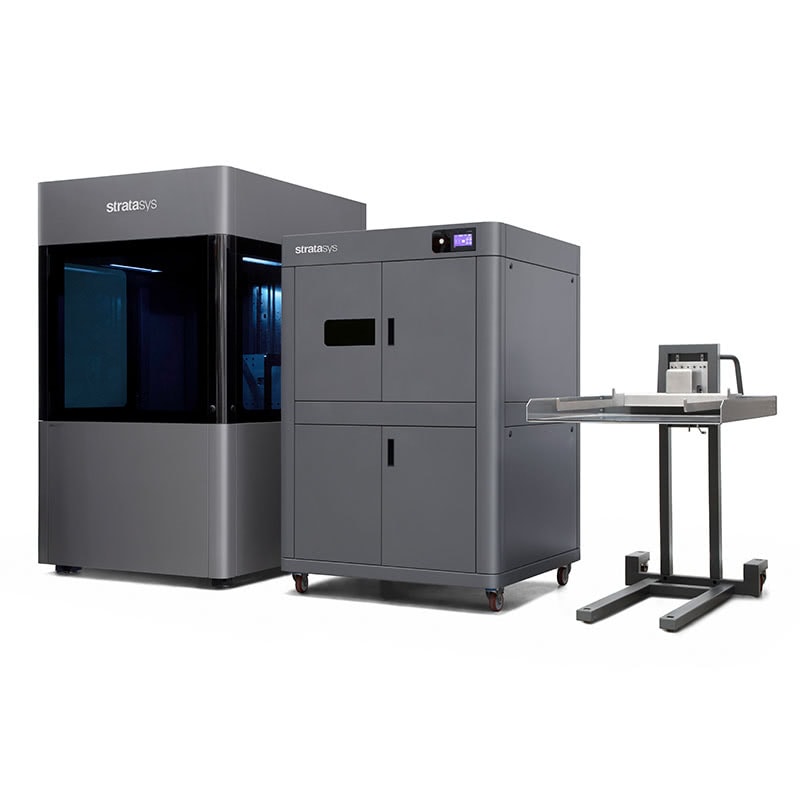

Stratasys Neo800

For those that need to produce large, accurate parts with exceptional levels of detail comes the Stratasys Neo800. Designed and manufactured in the UK by world-leaders in large-format Stereolithography (SLA), the Neo800 is a proven, reliable machine that can manufacture parts with excellent accuracy and detail.

A large build volume measuring 800 x 800 x 600mm lets you create larger parts without the need to divide them into smaller pieces. You can also save time by creating multiple, smaller parts in one build, rather than waiting for jobs to finish. Parts made with the Neo800 have exceptional sidewall quality, reducing the finishing time by as much as 50%. Perfect alternative to Neo450 – smaller version of stereolithography printer.

Key features

- Create parts with an exceptional surface finish using the large 800 x 800 x 600mm build platform.

- A dependable, high-performance machine used in industries as diverse as Formula One, service bureaus, universities and automotive environments.

- An open material system means users can use any 355nm SL resin, allowing the freedom of material selection.

- A high throughput helps to achieve greater cost efficiencies.

- A 2-Watt laser with dynamic beam shape control maintains maximum productivity and quality.

- The Neo800 can help to reduce finishing time by up to 50%.

- On-board camera and emailed progress reports keep you informed on a job’s status.

Titanium software

Manufacturing parts and managing print jobs is easy with the Titanium software that comes with every Neo machine. Featuring a build time estimator, material usage estimator and build validator, Titanium leverages the cameras built into every Neo printer to help you keep track on running jobs. The software helps to prolong material longevity by prompting you to take regular viscosity readings and logging the results.

Part traceability and Industry 4.0

Titanium integrates with Industry 4.0 systems via a RESTful API and shared file access. Its reporting tools help you understand how the machine is contributing to its business objectives. They also provide exceptional part traceability, enabling you to trace all parts back to a specific build and check the parameters used.

SIMILAR PRINTERS

SPECIFICATION

-

BUILD ENVELOPE

800 x 800 x 600 mm

-

SYSTEM SIZE

1350 × 1630 × 2300 mm; 800 kg

-

LASER

2 Watt

-

BEAM FOCUS

Dynamic & Variable

-

BEAM SIZE

150 to 600 μm

-

LAYER RESOLUTION

50 to 200 μm

CASE STUDY: AUTOMOTIVE

McLaren Racing — Advantage on the track with Stratasys Neo800

Stratasys’ Neo800 stereolithography 3D printers are enabling McLaren Racing to make up to 9,000 parts per...

MATERIALS

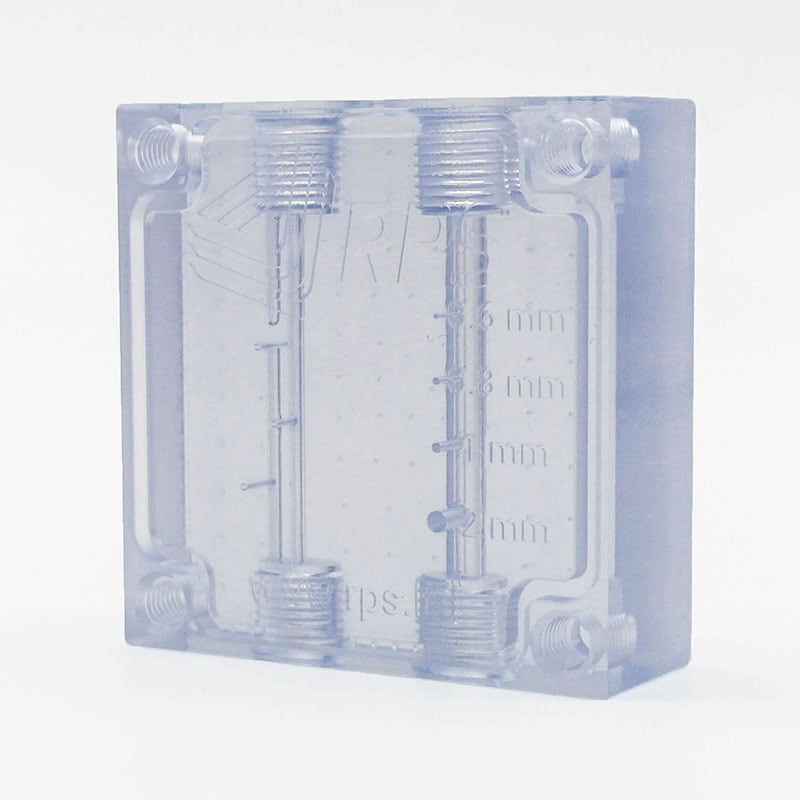

An open material system means users can use any 355nm SL resin, allowing the freedom of material selection and none of the usual parameter constraints.

In addition, the Neo 3D printers can run these technically advanced stereolithography materials: