Meet the winners of our world cup selfie competition

We love meeting all the people that attend The Engineer Design and Innovation Show (TEDIS), and this year we decided to do something a bit different. We challenged visitors to our stand to take a great selfie with a world cup that we printed on a Makerbot Z18 from our 3D bureau. The best picture won the opportunity to print a design of their choice on a Stratasys F370.

It was a hugely popular competition, with loads of outstanding entries, but the picture that impressed our judges the most was from a friendly group of student engineers at Bath University.

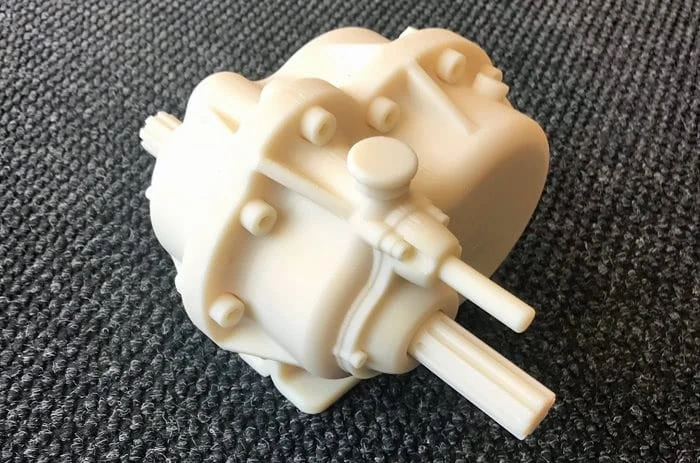

The printed part

The winners were Thomas Santini, Callum Woodward, Ben Woindrich and Adam Frey. They are studying for a masters degree in Integrated Design Engineering. Part of their first year course is designing a working manual gearbox. After putting their design into a CAD package, the students sent their .stl file to our bureau and received their prize part in the post just a few days later.

Spokesperson for the group, Thomas Santini, thinks that 3D printing is an excellent technology, thanks to its ability to create prototypes for a product very quickly.

“In ten years, I hope to see the general public more aware and involved in rapid prototyping, and for the process to begin challenging the popularity of conventional 2D printers”, says Thomas. “I would like to see the industry push the boundaries of what we can currently do, with augmented design coming to the fore.

“I believe that the point at which digital AI designs bring ideas into the physical world through multi-axis 3D printing will be the advent of the next age: the Augmented Age.”

Future plans

Thomas’ plans for the near future sound exciting: “I hope to develop my 3D printing skills by printing in more advanced filaments. I am interested in more advanced 3D printing systems, and throughout my degree I hope to help develop systems that help advance the 3D printing field.

“By doing practical research into ideas such as multi-axis printing and metamaterials. I hope to develop my skills by doing internships and work experience placements in companies that push the bounders of technology.”

“It’s great to see young people wanting to push 3D printing technology” says Laser Lines’ Richard Hoy, responsible for the bureau’s business development. “We loved printing the students’ design. With 18 machines on site in our Banbury base, we are excellently placed to produce a large range of designs extremely quickly. Just talk to us if you need any help turning your CAD drawing into a physical object.”

If you want to find out how our 3D printing bureau can help your business, get an online quote, give us a call on 01295 672599 or email [email protected].