Which metal 3D printer is right for my business?

Paul Tickle is Laser Lines’ Metals Product Specialist. Here he outlines the benefits of each of our metal 3D printers.

If you are looking for a metal additive manufacturing machine, we have plenty of options for you at Laser Lines. After selling and supporting 3D printing machines for over 25 years, we have amassed a lot of knowledge that we are happy to share with you.

All of our metal machines are perfect for prototyping and short production runs, but each of them has its own characteristics. The best one for you will depend on the sort of product you want to produce, so to discuss which one fits your needs, just give us a call on 01295 672599. In the meantime, here are the main types of customer that tends to select each machine:

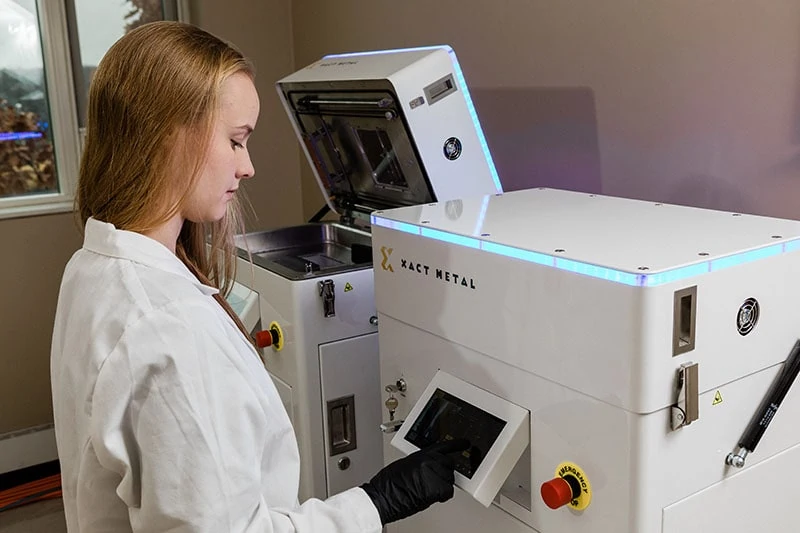

Xact Metal XM200C

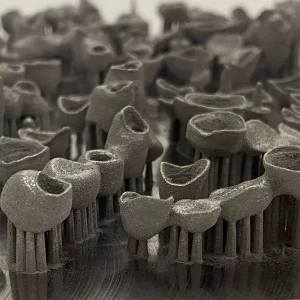

This is our best value system thanks to a technology known as the Xact Core system. This keeps the price of the system lower than its rivals, while maintaining the quality of the output. The Xact Core system uses a fast gantry to direct the laser by moving simple mirrors above the powder bed on an X-Y axis. This avoids the use of complex Galvanometers and F-theta lens. At 500mm/sec it’s fast enough for most customers, and thanks to the fine point laser, the surface finish and detail is excellent.

The build volume of this machine is 127 x 127 x 127mm so if an SME is looking for a great value entry machine, this is the one to go for.

Xact Metal XM200G

This makes it up to four times faster at producing a part than the XM200C. It also has a 15-inch touchscreen that lets you change the build parameters and see the job queue.

The build volume is larger at 150 x 150 x 150mm, and you can choose to buy the XM200G with a single 100W, 200W or 400W Yb fibre laser. Dual 100W, 200W and 400W Yb fibre laser versions are also available for Xact Metal’s fastest build times and the ability to assign each laser to a different area of the build tray.

Xact Metal XM200G Dental

Give Paul Tickle a call to discuss how metal additive manufacturing can benefit your business on 01295 672599 or email [email protected]