Full colour 3D printing, now available for your office

Save 97% in time compared to traditional CNC modelling, and 80% in costs.

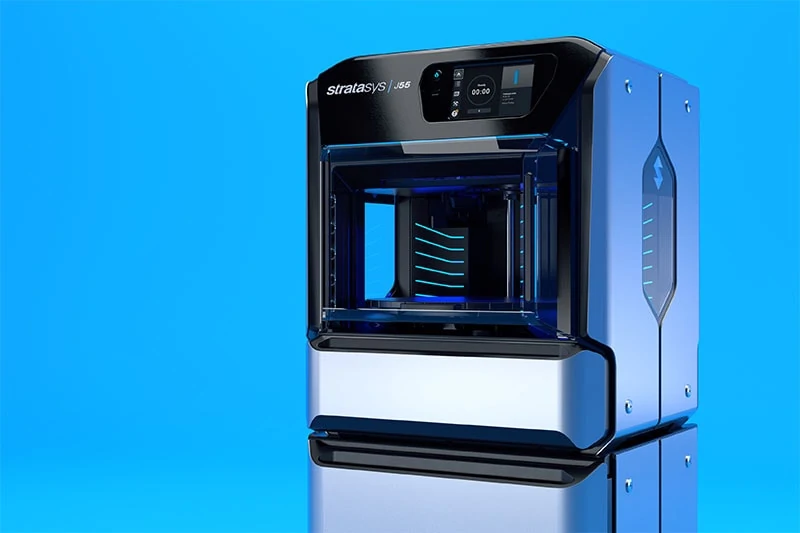

Say hello to the Stratasys J55, the first full-colour Polyjet 3D printer that doesn’t need a dedicated room or a specialised operator to run it. The Stratasys J55 fits into an office or classroom, and it is quiet enough to fit into a typical office without disturbing anyone.

“The key technological leap is the rotating tray,” says Phil Craxford, sales manager at Laser Lines. “Combined with a static print head, the rotating tray means the machine takes up a lot less space, while still producing the same high-quality, lifelike models we have come to expect from Stratasys Polyjet machines.”

The first of its kind rotating tray lets the machine achieve consistent material jetting, while the shorter, radial paths mean faster print times and outstanding quality.

No more odour

If you worked with a Polyjet machine in the past, you might have noticed a small odour when it’s working. This is no longer the case with the Stratasys J55. “This new machine features a ProAero Air Extractor. This external plenum system contains a mixture of chemical and HEPA filters to remove any smell or other fumes, allowing it to be placed in a normal office without any of the usual environmental protections,” says Phil.

At roughly half the cost of a Stratasys J826, the J55 is amazing value, and thanks to its small size you can fit more machines into your premises should you need them, increasing your prototyping yield.

Exceptional prototypes, fast

What sort of prototypes is the J55 good for? “The system has a huge range of applications,” says Phil. “Thanks to its multi-material ability and support for 500,000 colours, materials such as leather, wood and stone can easily be simulated, along with a wide array of matt and glossy surfaces.

“When you are right at the beginning of your design, you can use the DraftGrey material to produce concept models extremely quickly. Once you have your basic design established, you can add colour to the models and show all your stakeholder exactly what the finished product will look like. The printer is Pantone validated, which enables you to match the colours on your model to the final product, meaning no surprises when it hits the production stage.”

The J55 is convenient, then, but how much time does it save? “Stratasys has crunched the numbers on a typical project,” says Phil, “and you can save 97% in time compared to traditional CNC modelling, and 80% in costs.”

Phil is expecting interest in this new machine to be very high. “The 3D printing industry has been waiting for a machine like this for years, and we can’t wait to show it off to our customers.

“If you would like more information, please just get in contact and we will talk to you about whether it is the best fit for your needs, and fill you in on our very generous trade-in scheme, which gives you money off a new Stratasys machine in exchange for any 3D printer, in any condition.”

To find out more about the Stratasys J55, give Phil and the team a call on 01295 672599 or email [email protected].