Bombardier reduces production time by 77% with Stratasys F900

Bombardier Transportation is one of the largest manufacturers of rail equipment in the world, making everything from trains to signalling devices. After being in business for 45 years, it wanted to respond to its customers’ needs and become more agile, increasing the speed with which it could get a product to market, and giving the business more versatility to work on different projects at the same time.

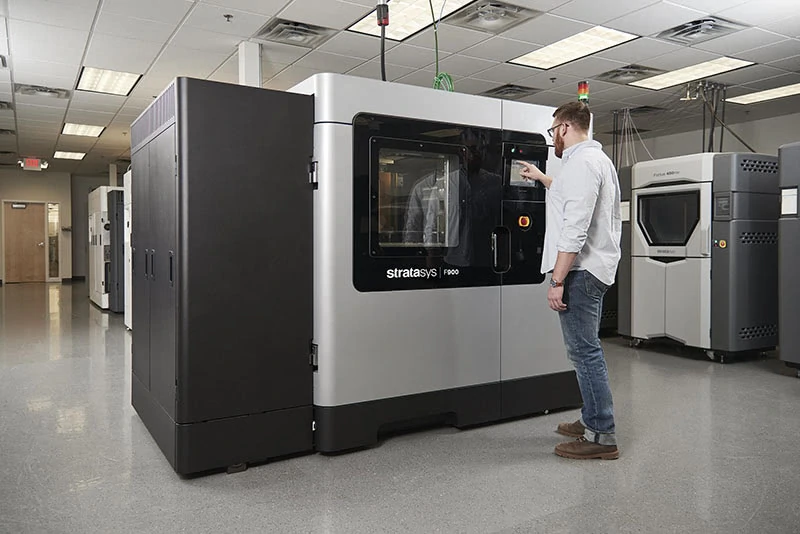

Enter the Stratasys F900, a 3D printer with a very large build volume that can produce production-ready parts in a fraction of the time it takes with traditional techniques. After purchasing a model for in-house use, Bombardier Transportation set it to work on a battery-powered prototype train it was designing.

Cutting production time

After designing an air vent for the train, the company printed it using ULTEM™ 9085 filament. Not only did this reduce the weight of the part compared to its normal manufacturing process, but the part was ready in just four weeks, compared to the four months it would usually take. Because ULTEM™ 9085 filament has already been certified for transportation use, the part was ready to use straight away.

“The Stratasys F900 was a game changer for our department” says André Bialoscek, head of vehicle physical integration at Bombardier Transportation. “With the battery train’s air duct, we were able to reduce production time by nearly 77%. That is an incredible outcome for our department and demonstrates our ability to now produce certain parts on-demand to exact needs without enduring lengthy production times or compromising on material quality.”

Cutting warehouse costs

But that wasn’t the only benefit the F900 bought Bombardier Transportation. Supporting all the different products it has manufactured over the years costs the company a lot of money in warehouse space, filled with all the spares for previous products in case they are needed one day.

Because the Stratasys F900 can be trusted to produce high-quality parts every time, Bombardier Transportation is building a digital inventory to replace the physical spares with virtual ones. By scanning the spares and storing them in CAD software, the company can simply use the F900 to print them as and when they are needed, rather than holding more inventory than is necessary, another large saving.

The company is so happy with its relationship with Stratasys, it is looking to deepen the partnership. André continues: “We are now also exploring Polyjet 3D printing technology for our design validation process, and the results we have witnessed so far have been convincing. The use of 3D printing to produce prototypes has seen us reduce our design process time by a massive 30-40%, while also increasing the quality of our overall designs.”

We can help you

“As we saw with another of our customers, GKN Aerospace, the Stratasys F900 frees companies from their usual manufacturing constraints, saving them time and money,” says Phil Craxford, Sales Manager at Laser Lines.

“Reducing lead times is vital in today’s complex manufacturing environment, and the reduction in storage costs 3D printing offers is substantial. As the UK’s leading seller and supporter of Stratasys 3D printers, we are well placed to help you analyse how much you could save by switching your production to additive manufacturing.”

Find out how the Stratasys F900 can benefit your business by calling Laser Lines on 01295 672599 or emailing [email protected]