You’re hired – Innovate Design chooses Laser Lines for The Apprentice product design printing

The Apprentice is one of the BBC’s flagship shows, and one of the most important elements of it is the design challenge, where the candidates’ abilities to launch a new innovative product are pushed to the limit.

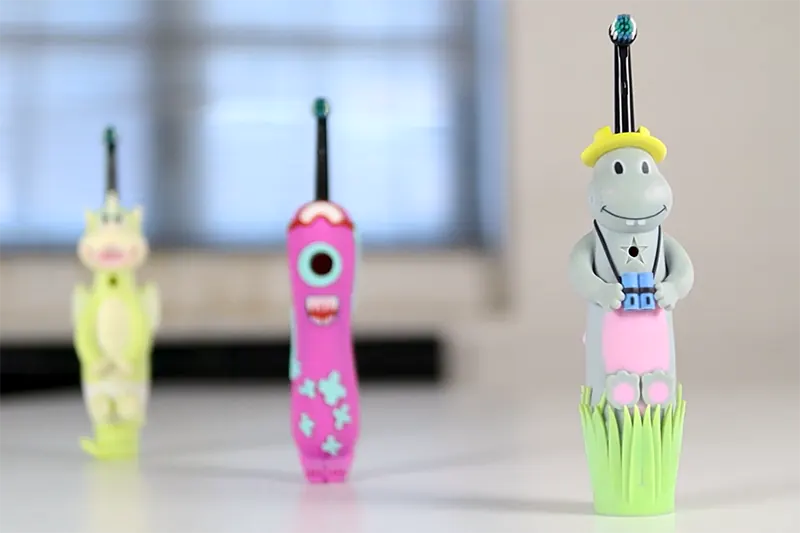

When product design company Innovate-Design was picked as the company to help design and print a product for the teams on this year’s The Apprentice, it had something to get its teeth into. In the programme, which aired in January 2022, candidates were asked to design an electric toothbrush and an app to encourage children to brush their teeth properly.

James McInerny, Co-managing Director at Innovate-Design, said: “We wanted to ensure the task was simple enough to complete in the tiny amount of design time we had, and the producers wanted to push the boundaries of previous series and pull off something incredible.

“We put together a multi-skilled team to handle the concept sketching, brush design, electronics and app development, character creation and packaging elements of the design. Each team of candidates needed their own set of designers so in the end it took quite a few of us.”

Innovate-Design created an internal chassis to mount the electronics which would sit inside the outer case that the candidates had designed. Even though the brushes were packed with new features and were only prototypes, everything fitted within a normal toothbrush size. Innovate-Design wanted the candidates’ brushes to be strong and be able to have a vibrant range of colours, so it selected a Stratasys J850 Prime polyjet 3D printer to produce the cases.

James added: “The toothbrushes looked amazing, but as time went on, production time scales became even tighter. We were really struggling to find a solution which would print in time. We even explored painting the brushes by hand, but it wouldn’t have dried soon enough!

“We knew the printers were rare, but we didn’t know how rare until we realised we needed a second one. It seemed there were only four of these highly specialised machines in the UK, and luckily we came across Laser Lines.”

With the deadline looming, Innovate-Design needed some assistance with getting some of the prototypes printed and turned to Laser Lines’ bureau facility to help them out. The prototypes were printed overnight at Laser Lines’ secure facility in Banbury on a Stratasys J850 Prime.

Greg Keech, Applications Engineer at Laser Lines, said: “The Stratasys J850 Prime is a fantastic device for designers in the consumer goods, electronics and automotive sectors as it enables you to get through the prototype stages faster, more efficiently and cheaper.

“A full-colour machine, the J850 Prime can print in over 500,000 colours, so you no longer need to paint your model by hand. It is certified by Pantone®, ensuring that the colour you choose at the design stage will be the same as the one used in production. The machine is twice as fast as previous generation J-series machines when in a new super-high-speed mode, and it can be loaded with seven materials at once.

“The build took a lot of organising between ourselves and Innovate-Design, as we had to follow the live recording of the show. This resulted in the bureau team coming in on Saturday as soon as the design had been completed by the candidates to put the build on the J850. Then we returned at 3am to remove it and meet the collection time at 4am so the parts could be in London for shooting by 6am.”

James added: “Having the Laser Lines’ bureau facility was a godsend and absolutely critical to getting the part out quickly and back to us ready for filming the next day. The Laser Lines team was amazingly knowledgeable, helpful, responsive and came back to us ASAP – something that we really appreciated. The brushes arrived just as we were getting up to assemble the prototypes. In the end, it couldn’t have gone smoother, and we are so grateful for the support from Laser Lines.”

Greg adds: “Thankfully we have the J850 Prime in the bureau for situations where a tight turnaround is needed. Its speed and efficiency are amazing. It was great to be able to help and to be part of such a high-profile, live production. In our opinion, it was the J850 Prime rather than the toothbrushes or Lord Sugar that stole the show!”

If you want to see how the Stratasys J-series of printers can help you get your prototypes made faster and more efficiently, email [email protected] or call 01295 672599 to find out more.

Watch the full story of the build below: