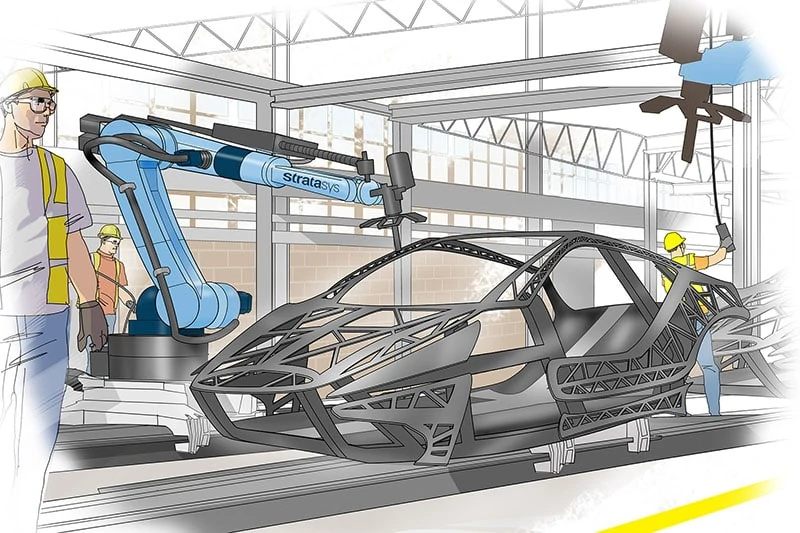

Additive manufacturing for composites saves time and money

Many companies in the composites industry are turning to additive manufacturing to save them time and money.

Typically, there are several difficulties faced by companies that haven’t made the switch to additive manufacturing, including:

- Long lead times leading to high costs

- High labour costs

- Difficulty making design changes

- Heavy tools that are large, difficult to move and store

Over time, the companies that have made the switch to FDM additive manufacturing have noticed several benefits, including:

- Reduced lead times

- Using the time saved to enable more iterations, changes and optimisations

- Giving you the ability to tailor the part or tool to the specific application, rather than designing one tool to fit multiple circumstances

- A faster response to any change in demand

- Parts and tools that are capable of withstanding high temperatures

Businesses have been able to achieve 75% savings in cost and time, reducing lead times from months to days.

Additive manufacturing and tooling

Now we have two documents that highlight the benefits of additive manufacturing for composites, including applications such as lay-up tooling, sacrificial tooling and coordinated tooling. The first contains many of examples of different companies using additive manufacturing to improve their business as well as a background to the design and build considerations.

Download composite tooling today: FDM applications & solutions use cases

The second offers an introduction to FDM additive manufacturing for composites, which has more detailed information on a similar range of topics, along with some guidance on what the future holds for additive manufacturing in this area.

Download an introduction to additive manufacturing for composites

If you want to find out more information about any of the themes discussed in the documents, please call Laser Lines on 01295 672599, or email us on [email protected].

With over 20 years of experience selling and supporting additive manufacturing machines, and as a Stratasys Platinum Partner, we are in an ideal position to support you. Our highly experienced staff are always available to talk through the best options for your business, offering advice on getting the best from additive manufacturing machines, and altering your designs to make them more efficient for this new way of working.