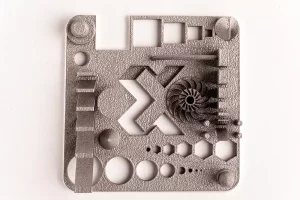

Xact Metal’s machines are some of the most affordable ways to move your metal production to additive manufacturing, with all the speed and cost savings that entails. These are powder bed machines, where metallic powder is fused, layer by layer, to form high quality, complex parts.

One of the exciting features about the Xact Metal machines that we sell and support is that they can support open-source materials. That means that it is possible to configure the machines so that they can be used with any metal powder, should you have a specialist need.

Most applications don’t need that level of configuration though. We sell powders that let you start the manufacturing process with the minimum of fuss, as all their parameters have already been set up in the machine.

Metal materials

Here are a selection of the powders that we supply that are ready to use:

- Aluminium

- Cobalt (9CoCr, CoCrMo)

- Copper (Al Bronze, C18150)

- Iron/ stainless steel (15-5PH, 17-4PH, 316L stainless steel, M300 tool steel)

- Nickel (Inconel 625, Inconel 718, Hastelloy X)

- Titanium (Ti64 Grade 5, Ti64 Grade 23, ELI)

There are plenty of applications for metal additive manufacturing across industries ranging from automotive, medical and dentistry sectors to oil/ gas, aerospace and marine.

Metal additive manufacturing benefits

Using an additive rather than traditional methods to manufacture metal parts has several huge advantages. One is that parts can be a lot lighter.

Because additive manufacturing builds a part layer by layer, you can make use of innovative, organic structures to give a part strength, rather than relying on a dense structure that is essentially a large lump of metal. That means you could, for example, build a part with lower cost stainless steel, while bringing the weight of the part down to the level it would be if it were made from aluminium.

There are lots of other examples of additive manufacturing improving the end part, as well as speeding up the time it takes to manufacture it. One of those is manufacturing a part such as a heat exchanger from copper. The shape and contours that you can produce using additive manufacturing are superior to those you can achieve in traditional manufacture. That results in improved fluid paths as well as less material being used overall. Potentially, that means you could reduce the size of the part and fit it into a tighter aperture.

As the UK supplier of Xact Metal machines and materials, we are more than happy to share our expertise with you and help you decide on the best material for your metal application, along with ideas for ways you can design your part to get the full benefits that additive manufacturing has to offer.

Give us a call on 01295 672599 or email [email protected] and speak to one of our experts today.