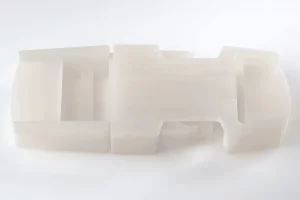

Durus: What you see is what you’ll get

- The original simulated polypropylene material.

- Excellent impact resistance.

- Produces precision sharp edges.

- Ideal for small cavity designs.

Leading 3D print material

Durus (RGD430) is the original Polyjet simulated polypropylene material. Popular with product design engineers for its impact resilience and elongation at break of 44% while remaining rigid, it is the ideal choice for modelling complex designs.

This material is particularly useful for 3D printing designs with delicate features and internal or external cavities. Your finished prototype will be an accurate representation of the finished product, allowing you to simulate usage and test design integrity with confidence.

Precision prototyping

Polypropylene is an essential material in domestic, commercial and industrial products. The ability to precisely model products with a polypropylene content allows design engineers and project managers to reduce prototype costs, move designs through the prototype process faster, reduce waste materials and save money over the life of the project.

Durus is particularly useful for modelling snap-fit features such as clasps and fasteners. It also works for living hinges and durable housings. With an accurate finish, designers can see exactly what the manufactured product will look like, helping to inform design modifications.

You can use Durus with several different Stratasys printers, including selected models from the Objet series. The material is available in ivory, which makes the features of delicate or complex parts stand out.

Design projects made easy with Polyjet materials

Polyjet materials simulate a wide range of industrial materials, helping to reduce time-to-market and overall cost for design and research projects. Businesses are increasingly adopting 3D printing technologies, and PolyJet materials are used across aerospace, medical, consumer products, automotive and dental sectors. They are used for concept modelling, composite tooling, injection moulding, rapid prototyping and surgical modelling, among other applications.